Check valves, also known as non-return valves, are used in fluid pipeline systems. They rely on the flow of the medium in the pipeline to generate power, automatically opening and closing to prevent backflow in the pipeline. They are effective in preventing the reversal of water pumps and their drive motors, as well as the release of media in containers.

Check valves are favored for their short length, small size, light weight, simplicity, and compact design, making them widely applicable in engineering systems.

There are three structural forms of check valves: lift type, swing type, and butterfly type. The swing type further divides into single-disc swing and double-disc swing. The execution standard is JB/T 8937-2010 for check valves.

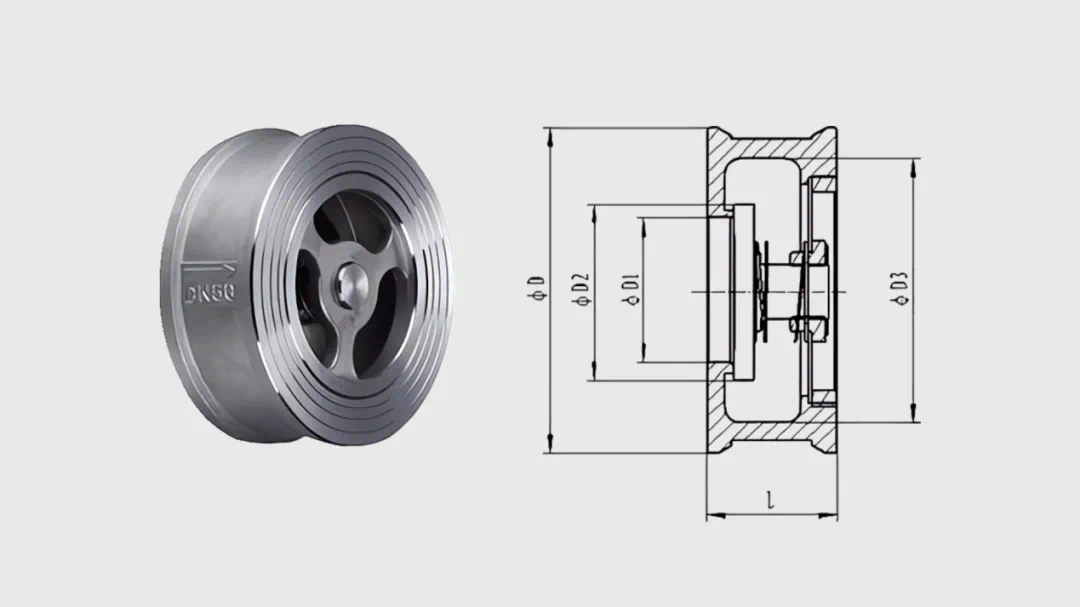

There are two models for the clamp lift check valve: H71 and H72

H71 clamp lift check valve consists of a valve body, valve disc, spring, and positioning plate. It is equipped with a spring, but the valve disc is unidirectional. It is recommended for installation in vertical pipelines, although it can also be used in horizontal pipelines. The diameter is ≤DN350.

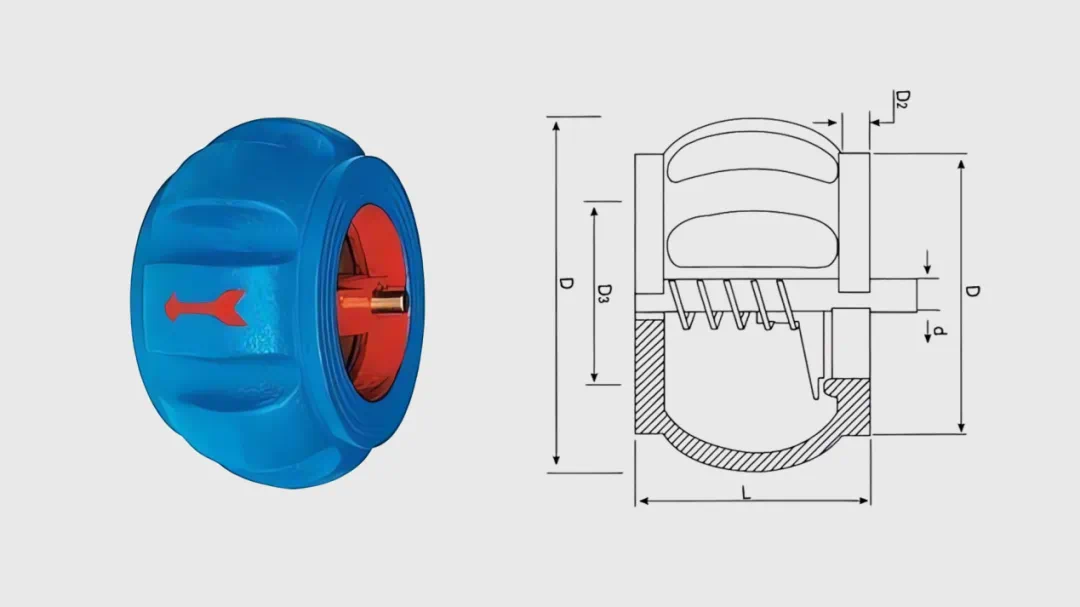

H71X Pumpkin-shaped clamp-type silencing check valve. Used in low-pressure water systems. The structural length is shorter than the H41X flange-type silencing check valve. Its appearance resembles a pumpkin, also known as a pumpkin-shaped clamp check valve. The valve body is made of ductile iron. It can be installed in both vertical and horizontal pipelines.

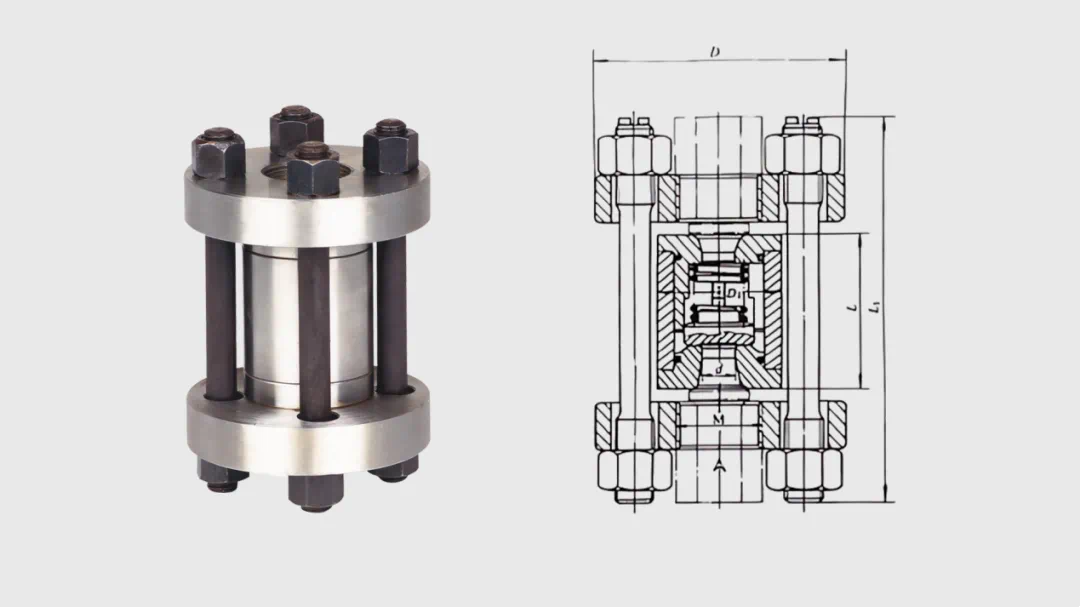

The HT2H high-pressure double-disc check valve, due to its compact structure, convenient manufacturing and maintenance, and reliable operation, is widely used in the high-pressure systems of synthetic nitrogen production units. After connecting with threaded flanges and pipes, it is sealed with a lens gasket and valve. The check valve inside the two flanges is clamped together with bolts. The nominal pressure is PN160 and PN320.

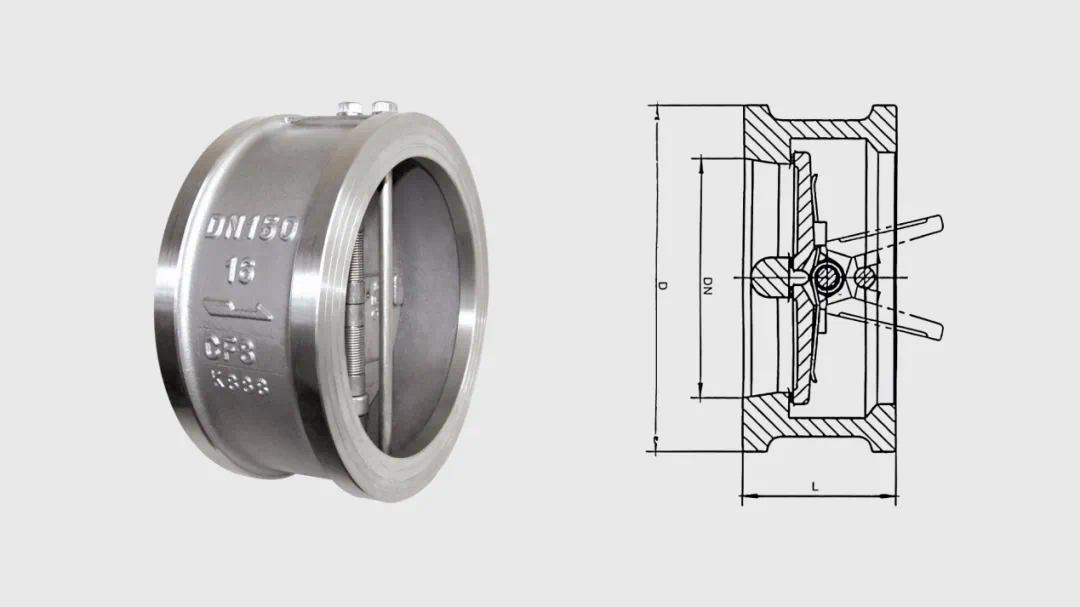

H76 clamp double-disc swing check valve.It is mainly composed of a valve body, valve disc, valve seat, torsion spring, pivot, and other components. The valve disc is made up of two semi-circular discs. When open, the two discs fold together, and when closed, they form a complete circle. It closes more rapidly than a single-disc swing check valve. The diameter can reach up to DN2000.

H74 clamp single-disc swing check valve (short series)

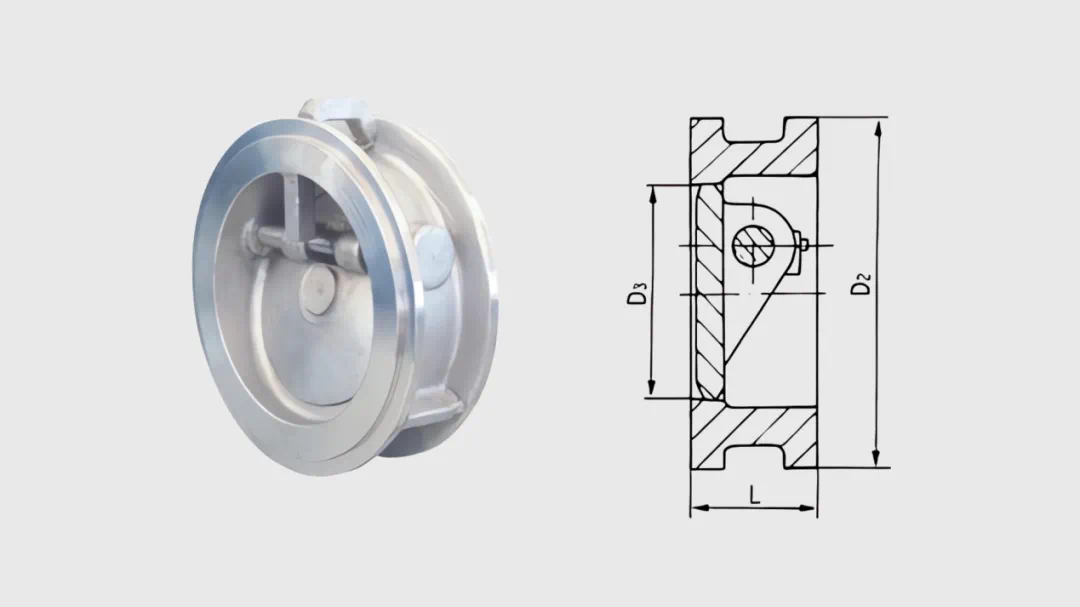

The H74 clamp single-disc swing check valve is available in short series and long series. The short series has an extremely short valve body length, with the valve disc and pin integrated, precisely accommodating the thickness of the valve disc. It is also known as a clamp thin-type check valve.

Compared to the H44 flanged check valve of the same caliber, it significantly reduces the weight of the valve body and decreases the valve size. The valve disc can be equipped with a reset spring for pipelines with significant pressure fluctuations, reducing water hammer phenomena.

It comes in two forms: hard sealing and soft sealing. In the soft sealing form, an O-ring is added to the sealing groove for easy replacement. The flange sealing of the valve body can also adopt an O-ring sealing form, replacing the flange sealing gasket, which is very convenient. Due to product structure reasons, there is a reduced diameter at the flow passage.

H74 clamp single-disc swing check valve (long series).

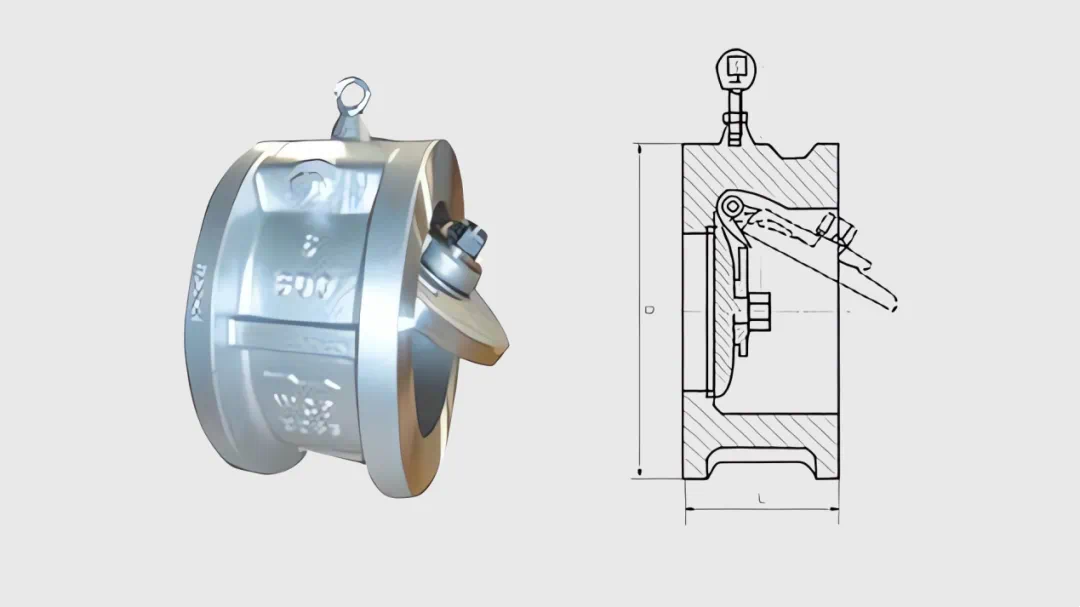

Compared to the short series of H74 swing check valve, the long series of clamp single-disc swing check valve inherits most of the features of the H44 flanged check valve, including the valve disc, rocker arm, pin, etc. The length of the valve body is longer than the short series. The valve disc with a spring can close more rapidly, enhancing the sealing performance of the valve disc.

H77 clamp butterfly check valve

The butterfly check valve has the valve disc rotating around the internal pin axis of the valve seat, while the swing check valve has the valve disc rotating around the external pin axis of the valve seat. This is the main structural difference between the two.

H77 clamp butterfly check valve has both a vertical type and an inclined type of valve disc, similar to the structure of a triple eccentric butterfly valve. Flanged butterfly check valves are mostly used in large-diameter pipelines, reaching up to DN2000, and adopt a slow-closing structure.

Installation requirements and precautions:

Do not directly connect with the clamp butterfly valve. Otherwise, it may cause interference between the butterfly valve and the check valve disc when they are both open, leading to damage to the valve disc.

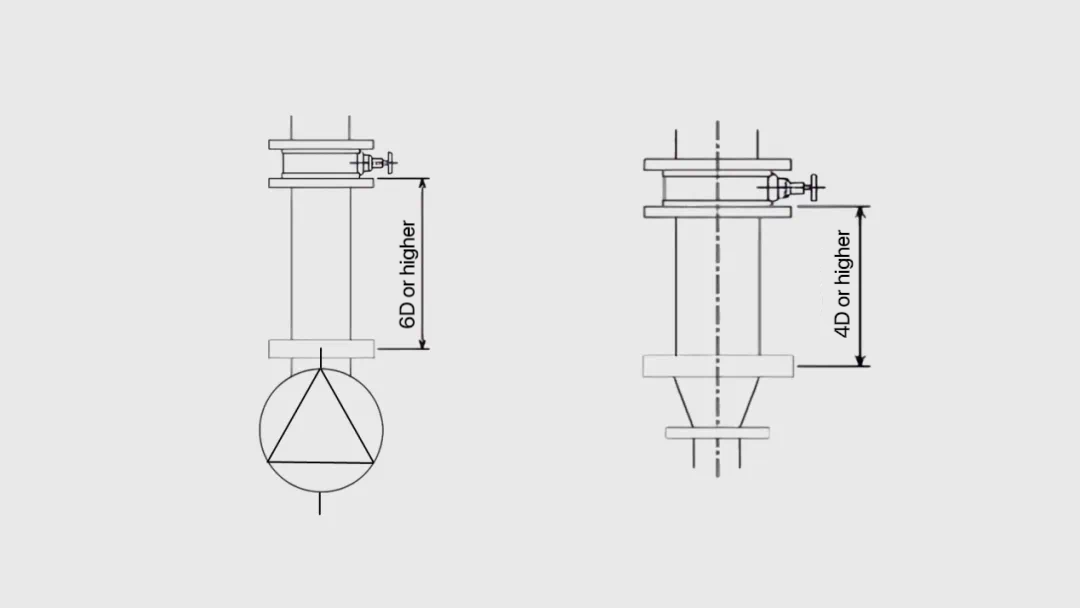

When installing the clamp check valve at the outlet of a water pump, ensure a straight pipe section distance of at least 6 times the pipe diameter. When installing the clamp check valve near joints in pipes of different sizes, maintain a straight pipe section distance of at least 4 times the pipe diameter.

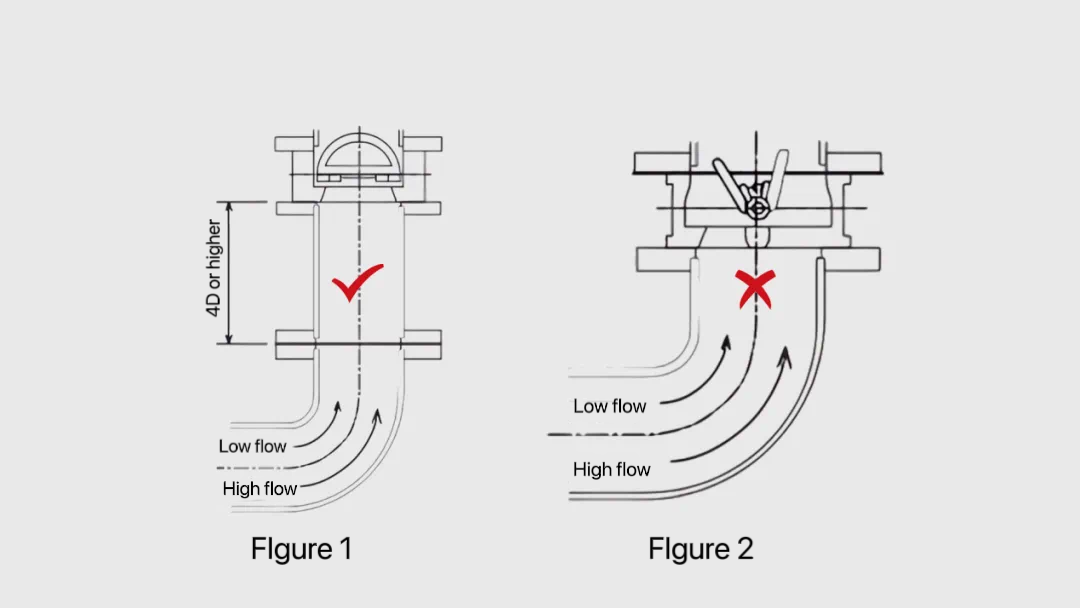

When installing the clamp check valve near a curved pipe, ensure a straight pipe section distance of at least 4 times the pipe diameter. When using a double-disc clamp check valve, to ensure the valve disc can withstand the effects of balanced flow velocity, it is recommended to install it according to the method shown in Figure 1.

In pipelines where internal leakage is not allowed, it is advisable to choose a soft-sealed check valve because hard sealing (metal sealing) may sometimes experience internal leakage. Even with a soft-sealed check valve, internal leakage may occur when there is no pressure difference between the inlet and outlet.

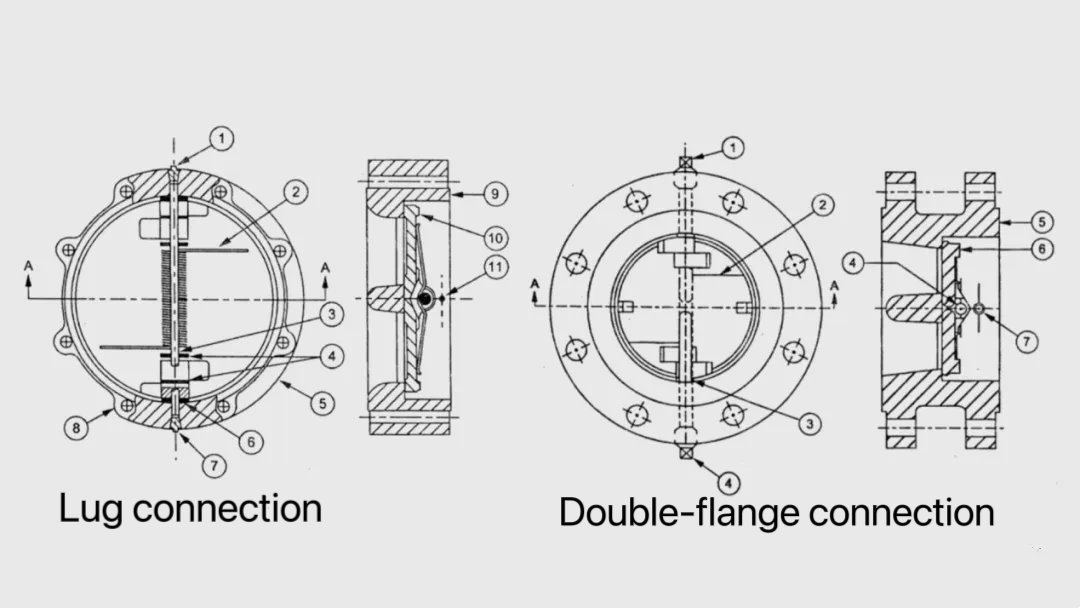

In addition to using clamp connections, clamp check valves can also be installed using lug connections or double-flange connections.