In the procurement of butterfly valves, you often hear terms like “valve with pin” and “valve without pin.” Due to process reasons, valves without pins are usually more expensive than those with pins. This leads many customers to wonder if a valve without a pin is better than one with a pin. So, how do valves with pins and those without pins compare?

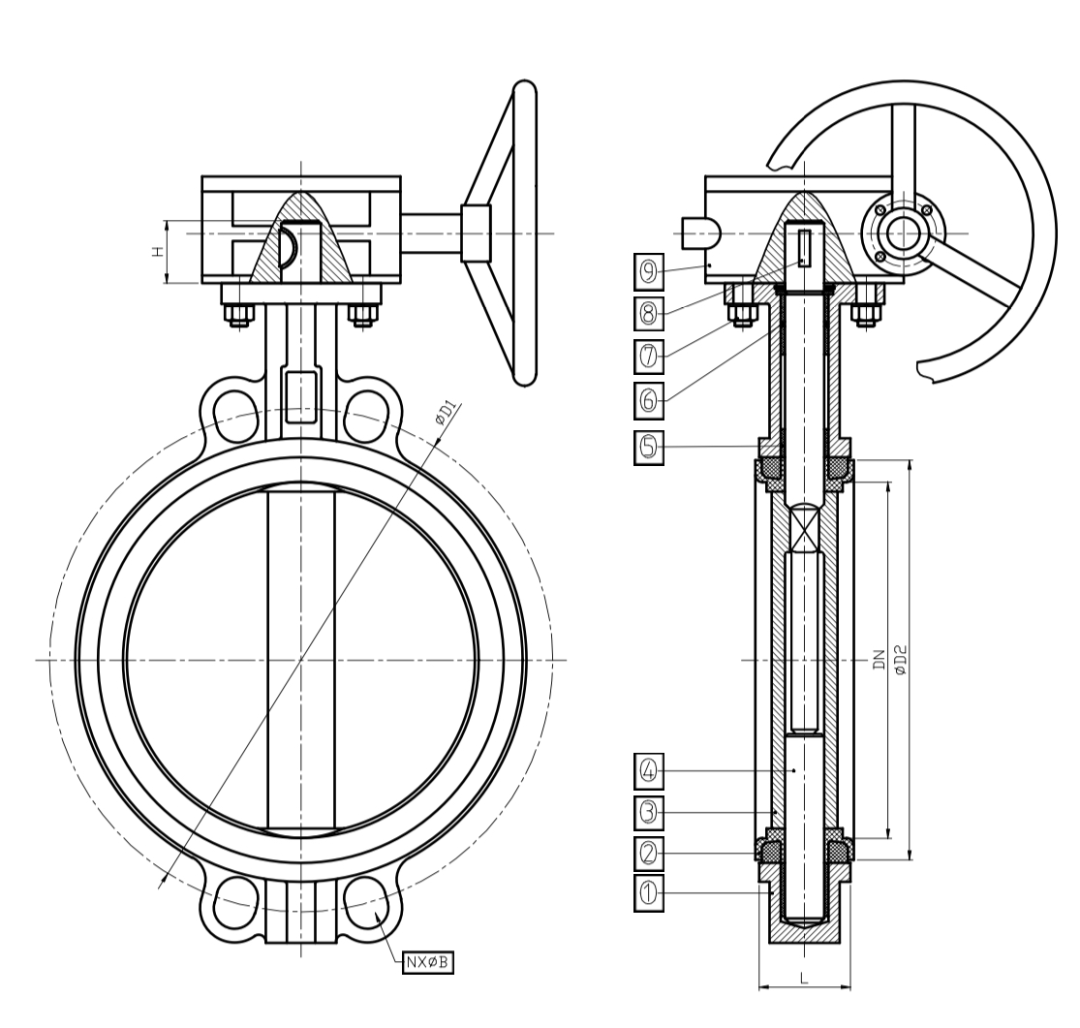

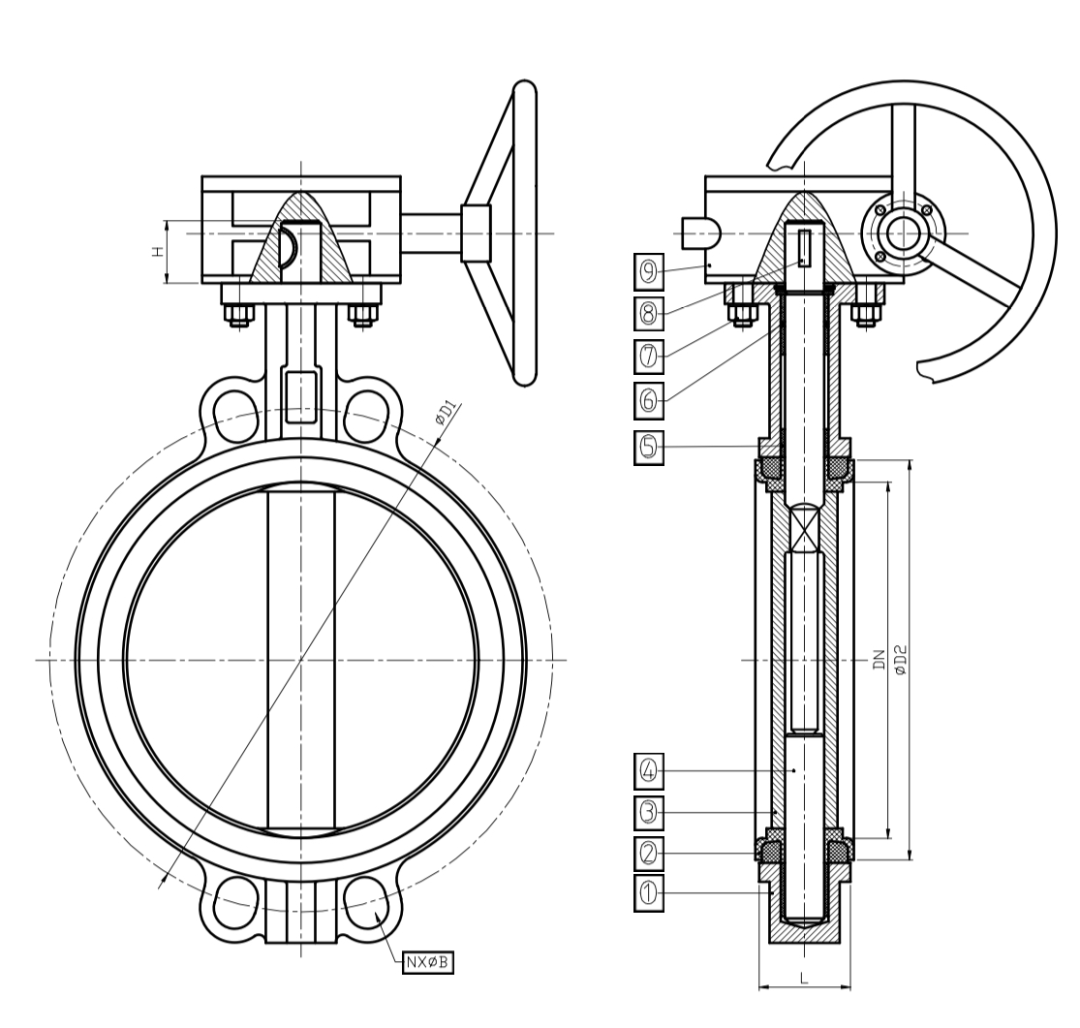

The most fundamental difference between butterfly valves with pins and those without pins is evident in their appearance: the presence or absence of a conical pin for positioning on the valve disc. If the connection between the valve disc and the stem involves a pin piercing through them, it is a valve with a pin. Conversely, if there is no such pin, it is a valve without a pin. Both types of valves, with and without pins, have their own advantages and disadvantages.

Comparison of Specifics:

Appearance:

In terms of appearance, butterfly valves with pins have noticeable pin heads protruding, giving them a less smooth and aesthetically pleasing look compared to pinless butterfly valves. However, the impact on the overall appearance is not particularly significant.

Processing:

The processing of butterfly valves with pins is relatively simple, but disassembly for maintenance can be troublesome when removing the stem and valve disc. The pins are typically press-fit using a press machine, making it challenging to extract the stem. Pinless butterfly valves, on the other hand, have a more complex structural process due to the different torque transmission method. However, they are more convenient for maintenance and disassembly in the long run.

Stability:

The stability of butterfly valves with pins is better due to the presence of pins for fixation. Pinless structures may experience wear on the shaft and disc mating surfaces over prolonged use, affecting operational accuracy.

Sealing:

Regarding sealing effectiveness, there’s a concern that medium may penetrate from the pinning point into the space between the valve disc and stem in butterfly valves with pins. This potential issue could lead to corrosion and fracture of the pin over time, rendering the valve inoperable or causing stem leaks and internal pipeline leaks.

Conclusion:

In summary, when comparing butterfly valves with and without pins, each design has its distinct advantages. It’s not straightforward to declare one better than the other. The key is to choose the product that best fits your cost budget and aligns with the conditions of your specific application. The suitability of a product depends on how well it matches your requirements.