The valve industry in China has made significant advancements over the past few decades. China is one of the largest producers and exporters of valves globally, with a vast number of valve manufacturing companies and a mature supply chain system.

Chinese valve manufacturers are committed to improving product quality and technological innovation to meet the demands of both domestic and international markets. They have made significant progress in the design, manufacturing, and sales of various types of valves.

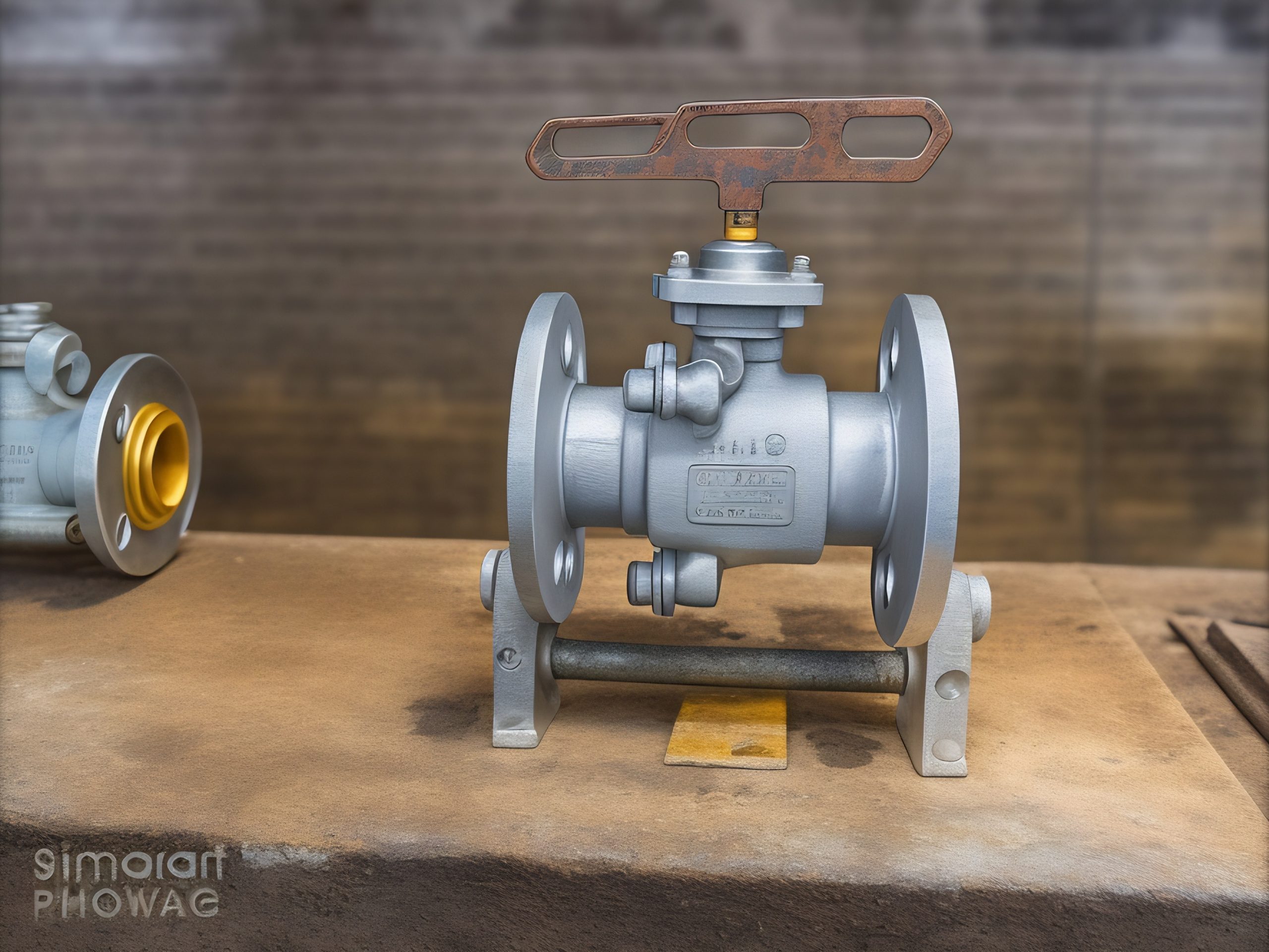

Valve Classification:

There are numerous types of valves, including ball valves, gate valves, globe valves, check valves, filter valves, bottom valves, diaphragm valves, sight glass valves, knife gate valves, needle valves, plug valves, pressure relief valves, safety valves, insulation valves, cryogenic valves, bellows valves, oxygen valves, ammonia valves, control valves, shut-off valves, steam traps, ceramic valves, breathing valves, butterfly valves, drain valves, discharge valves, float valves, and many more.

Valve Operating Categories:

Valves can be categorized as manual valves, pneumatic valves, electric valves, hydraulic valves, and others.

Different Configurations for Various Environments:

Valves can be configured for high-temperature applications, low-temperature applications, high-pressure applications, low-pressure applications, corrosion-resistant valves, wear-resistant valves, food-grade valves, marine valves, power plant valves, oil-free valves, demagnetization valves, and more.

Application Fields of Valves:

Valves find applications in residential construction, chemical plants, food factories, pharmaceutical plants, chemical production plants, power plants, shipbuilding plants, oil refineries, wastewater treatment plants, machinery equipment factories, environmental projects, dairy plants, breweries, domestic water supply, HVAC systems, metallurgical industry, mining industry, and various other fields.

Valve Materials:

The main materials used for valves include carbon steel (WCB), stainless steel (TP304, TP304L, TP316, TP321), and special materials such as 2205, 2507, 904L, titanium (TA2, TA6), Hastelloy alloys (C276, C22, C4), Monel alloy (MONEL400), Inconel alloys (INCONEL600, 601, 800, 825), SM254, 316Ti, 317L, 347H, 1Cr13, and others.

Valve Production Processes:

Valves are currently produced using different casting processes, including sand casting, precision casting, water glass casting, forging and casting, die-casting, and investment casting.

Valve Standards:

Valve standards define international or industry standards for valve design, manufacturing, inspection, and testing.

- API Standards: The American Petroleum Institute (API) has developed several valve-related standards, such as API 600 (steel gate valves), API 602 (steel check valves), API 609 (butterfly valves), API 598 (valve inspection and testing), and others.

- ASME Standards: The American Society of Mechanical Engineers (ASME) has published various standards related to valves, including ASME B16.34 (valves – steel valve specifications), ASME B16.10 (face-to-face dimensions of valves), and others.

- DIN Standards: The German Institute for Standardization (DIN) has released a series of valve standards, such as DIN 3352 (metal gate valves), DIN 3202 (marking of metal valves), and others.

- EN Standards: The European Committee for Standardization (CEN) has developed a range of valve standards, including EN 593 (butterfly valves), EN 12516 (industrial valves – pressure testing of valve bodies and covers), and others.