Description

Data Sheet

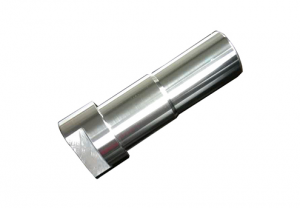

-Full port, 1/4″-4″(DN6-DN100)

-W.P.:1000WOG(PN63)

-W.P.:-20℃-180℃

-Investment casting

-Blow-out proof stem

-Locking device handle (option)

-Thread type: ASME B1.20. 1 (NPT),

NIN 259/DIN 2999, BS 21,

ISO 288-1, ISO 7-1

Two-piece b all valves have the following characteristics:

all valves have the following characteristics:

- Quick switching: Due to the simple rotational operation of the ball valve, it can switch rapidly, making it suitable for applications that require fast control of fluid flow.

- Strong durability: The ball of the valve is typically made of corrosion-resistant materials such as stainless steel or copper alloys, providing high durability and reliability.

- Good sealing performance: The minimal contact points between the ball and the sealing surfaces result in relatively good sealing performance, reducing the risk of leakage.

- Wide applicability: Two-piece ball valves can be used for various media control, including liquids, gases, and low-pressure steam.

It is important to note that two-piece ball valves are suitable for smaller pipe sizes and are typically used in low to medium-pressure applications. For larger pipe sizes and high-pressure environments, other types of ball valves or valves may be required to meet the specific requirements.

The valve body is made of precision cast stainless steel materials such as 304, 316, 316L, 2205, and others.

- Preparation: The appropriate stainless steel materials are mixed in the correct proportions and subjected to high-temperature melting to obtain a liquid stainless steel alloy.

- Casting: The molten stainless steel is injected into prepared molds, filling the mold cavities and ensuring even distribution of the material.

Cooling and Solidification: The injected stainless steel cools and gradually solidifies, allowing the part to maintain its precise shape during the casting process.

Cooling and Solidification: The injected stainless steel cools and gradually solidifies, allowing the part to maintain its precise shape during the casting process.- Removal of Castings: Once the stainless steel has completely solidified, the castings are removed from the molds. Some deburring or surface treatments may be required.

- Post-processing: Additional post-processing steps such as heat treatment, machining, polishing, etc., may be carried out as needed to achieve the final precision stainless steel components.

Precision casting of stainless steel enables the production of various complex stainless steel components such as pipe fittings, valves, pump bodies, automotive parts, and more. It finds wide applications in industries such as aerospace, medical equipment, petrochemicals, food processing, and others. This process offers high precision, strength, and excellent corrosion resistance for stainless steel components.

The valve ball is a critical component of a valve and serves as the core part of a ball valve. It is typically a spherical structure used to control the flow of media by rotating it. The valve ball is made of corrosion-resistant materials such as stainless steel, copper alloys, or other materials that can withstand high temperatures and pressures.

The characteristics of the valve ball are as follows:

- Spherical Structure: The valve ball has a spherical shape with a hollow channel. When the ball rotates, the channel can align or close with the pipeline, thereby controlling the flow of the media.

- Corrosion Resistance: Since the valve ball comes into direct contact with the media, it is usually made of corrosion-resistant materials to ensure long-term reliable operation.

- Sealing Performance: With fewer contact points between the valve ball and the sealing surfaces, it exhibits good sealing performance when in the closed state, effectively preventing leakage.

- Strength and Pressure Resistance: The valve ball needs to have sufficient strength and pressure resistance to withstand the forces and pressures in the working environment.

- Adjustability: The rotation angle of the valve ball can be adjusted as needed, ranging from fully open to fully closed, enabling precise flow control.

Valve balls are widely used in ball valves, control valves, and some specialized valves. They play a crucial role in industries such as petrochemicals, chemicals, power generation, water supply, and drainage systems, providing reliable fluid control and regulation functions.

Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a high-performance polymer material with unique properties and a wide range of applications.

Here are the key characteristics and properties of PTFE:

- Nonstick: PTFE is well-known for its nonstick properties, providing excellent lubrication. This makes it widely used in applications involving friction and sliding, such as lubricating seals, bearings, and valves.

- Corrosion Resistance: PTFE exhibits high resistance to most chemicals, including acids, alkalis, solvents, and other corrosive substances. It is used in the chemical industry to manufacture corrosion-resistant pipes, valves, and containers.

High Temperature Stability: PTFE has excellent high-temperature stability, maintaining its physical and chemical properties at extreme temperatures. It can operate for extended periods at temperatures up to 150 degrees Celsius without melting or decomposing.

High Temperature Stability: PTFE has excellent high-temperature stability, maintaining its physical and chemical properties at extreme temperatures. It can operate for extended periods at temperatures up to 150 degrees Celsius without melting or decomposing.- Electrical Insulation: PTFE is an excellent electrical insulation material, offering good insulation properties and a low dielectric constant. It finds widespread applications in electronic devices, wires, cables, and insulating components.

- Mechanical Properties: PTFE possesses good mechanical strength and wear resistance. It can withstand high pressures and tensile stresses while maintaining a low coefficient of friction and excellent resistance to wear.

These characteristics make PTFE a versatile material used in various industries, including aerospace, automotive, chemical processing, electrical, and many others.

The valve stem is an important component of a valve and is usually connected to the valve core or disc to control the valve’s opening and closing or regulating functions. It serves as the transmission component of the valve, carrying the operating force applied to the valve.

The main functions of the valve stem include the following aspects:

- Transmission of Force: The valve stem transfers the operating force to the valve core or disc, enabling the valve to perform its opening, closing, or regulating functions.

- Support and Guidance: The valve stem provides support and guidance within the valve, ensuring stable movement of the valve core or disc and reducing friction.

- Sealing: In certain types of valves, the valve stem needs to have sealing capabilities to prevent media leakage. Sealing devices such as packing or seals are typically used between the valve stem and the sealing surfaces of the valve.

- Corrosion Resistance: As the valve stem is exposed to the media, particularly corrosive media, it is necessary to select materials with good corrosion resistance for manufacturing the valve stem, such as stainless steel or alloy materials.

- Wear Resistance: The valve stem needs to have sufficient wear resistance to withstand friction and wear during valve operations.

The design and material selection of the valve stem should be based on the specific valve type, operating conditions, and characteristics of the media. Common materials used for valve stems include stainless steel, carbon steel, copper alloys, while specialized valves may employ special materials or surface coatings to enhance their performance.

In summary, the valve stem plays a crucial role in the operation and control of a valve, and its design and material selection have significant impacts on the valve’s reliability, sealing performance, and durability.

Reviews

There are no reviews yet.