Description

Data Sheet

– Full port, 1/2–6° (DN15~DN150)

– W.P.: CLASS 150/300

– W.T.: -20°C~180°C

– Investment casting

– Blow- out proof stem

– Anti-static device (option)

– Design: ASME B16.34,AP1608,API6D

– Flange dimension: ASME B16.5

– Face to face: ASME B16.10

– Inspection & testing: AP1598

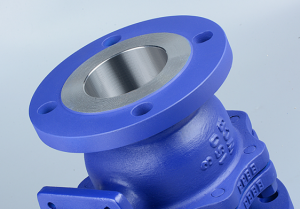

American Standard Carbon Steel Ball Valve Introduction:

The valve body is thickened for added strength and durability. It ensures robustness and can withstand higher pressures and tougher operating conditions.The valve is designed for easy operation, allowing for convenient opening and closing. This feature facilitates smooth and efficient control of fluid flow.The valve incorporates a stainless steel ball within its structure. Stainless steel is a corrosion-resistant material, providing excellent longevity and reliability. The stainless steel ball ensures smooth rotation, minimal wear, and reliable sealing performance, reducing the risk of leaks or failures.

reducing the risk of leaks or failures.

The valve undergoes international standard environmentally-friendly paint coating, ensuring a protective layer that is resistant to rust and corrosion. This coating not only provides aesthetic appeal but also enhances the valve’s durability and longevity.

The imported anti-rust layer paint is used to further enhance the valve’s resistance to rust and corrosion, particularly in harsh or corrosive environments. This ensures the valve’s performance and extends its service life.

The valve is subjected to a meticulous grinding process, starting from coarse to fine, to achieve a smooth and polished surface. This process not only improves the valve’s appearance but also helps to minimize surface imperfections and ensure optimal functionality.

only improves the valve’s appearance but also helps to minimize surface imperfections and ensure optimal functionality.

These measures ensure that the valve is well-protected, visually appealing, and able to withstand various environmental conditions while maintaining reliable performance.

Low-platform ball valve is a specially designed valve with the following features:

- Central shaft valve bonnet: The low-platform ball valve utilizes a central shaft valve bonnet structure, providing better stability and sealing during valve opening and closing. The design of the central shaft valve bonnet ensures accurate alignment of the ball within the valve and offers balanced valve operating forces.

- Directional positioning plate: The low-platform ball valve is equipped with a directional positioning plate to ensure precise alignment and sealing of the ball when the valve is closed. The directional positioning plate prevents ball displacement or deviation during operation, thereby improving the valve’s reliability and sealing performance.

- Stainless steel valve body central axis: The low-platform ball valve features a stainless steel valve body central axis. This component ensures the alignment and stability of the valve, contributing to its overall performance and durability.

Overall, the low-platform ball valve incorporates these design elements to enhance its stability, sealing capabilities, and reliability.

The purpose of painting carbon steel valves is to provide additional corrosion protection and aesthetic appeal. Painting helps prevent oxidation and corrosion on the surface of carbon steel valves, thereby increasing their durability.

Here is a general process for painting carbon steel valves:

- Surface Preparation: The valve surface is prepared by cleaning and removing any dirt, rust, or contaminants. This step ensures proper adhesion of the paint and enhances the effectiveness of the coating.

- Primer Application: A layer of primer is applied to the valve surface to provide good adhesion and corrosion protection. The choice of primer should be based on the valve’s operating environment and requirements.

- Coating: Once the primer is dry, the desired coating is applied evenly to the valve surface using appropriate spray equipment and paint. Multiple coats may be applied for better protection and color effects.

- Drying and Curing: After the painting process is complete, the valve should be dried and cured under suitable conditions to ensure the quality and durability of the coating.

The painting process enhances the corrosion resistance and visual appearance of carbon steel valves, ensuring their longevity and suitability for various environments.

Reviews

There are no reviews yet.