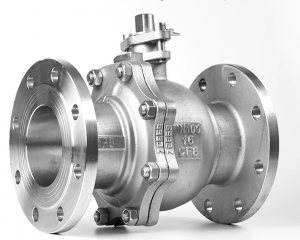

Description

Data Sheet

– Full port, 1/2’~6″ (DN15~DN150)

– W.P.: PN16/40

– W.T.:-20°C~180℃

– Investment casting

– Blow-out proof stem

– Anti-static device (option)

– Design: GB /T 12237

– Flange dimension: HG /T 20592

– Face to face: GB / T 12221

– Inspection & testing: GB / T 13927, JB / T 9092

Here are some characteristics and applications of stainless steel flanged ball valves:

- Stainless steel material: The valve body and internal components of stainless steel flanged ball valves are typically made of stainless steel materials, such as stainless steel 304, stainless steel 316, 2205, 31803, and other special alloys. These materials offer excellent corrosion resistance, withstanding the effects of acids, alkalis, and other corrosive media.

- Flanged connections: The valve body of a stainless steel flanged ball valve is designed with flanged connections for easy installation and secure connection to the pipeline system. Flanged connections provide reliable fastening and sealing, ensuring a strong and leak-free connection between the valve and the pipeline.

- Fluid control: Stainless steel flanged ball valves operate by rotating the ball to control the flow of the medium. The opening and closing of the ball enable quick on/off operation, making them suitable for applications requiring rapid flow control.

- Pressure resistance: Stainless steel flanged ball valves typically have high-pressure resistance capabilities, allowing them to withstand high-pressure and high-temperature working conditions.

- Application areas: Stainless steel flanged ball valves are widely used in chemical, petroleum, pharmaceutical, food processing, water treatment, and other industries. They are commonly employed to control the flow of liquids or gases, especially in corrosive media, high-temperature environments, and high-pressure applications.

Normal ball valves and high-temperature ball valves have differences in terms of operating temperatures. Here are the general temperature ranges for each:

- Normal Ball Valves: Normal ball valves are typically suitable for applications at regular temperatures and have a temperature range of approximately -20°C to 200°C. These types of ball valves are widely used in general industrial fields and low to medium temperature environments.

- High-Temperature Ball Valves: High-temperature ball valves are specifically designed for high-temperature applications. They are constructed with special materials and structures to meet the demands of high-temperature environments. The temperature range for high-temperature ball valves is usually above 200°C, reaching several hundred degrees Celsius or even higher.

It’s important to note that the specific temperature ranges may vary depending on the type of ball valve, material selection, and manufacturer. When selecting and using ball valves, it’s crucial to consult the manufacturer’s product specifications and technical data to ensure that the ball valve’s temperature range aligns with the actual requirements.

Additionally, high-temperature applications require special considerations for sealing materials, seat materials, and stem materials to ensure the reliability and safety of the ball valve in high-temperature environments. For extremely high-temperature applications, additional measures may be necessary, such as cooling measures, insulation layers, or the selection of special metallurgical materials, to meet the requirements.

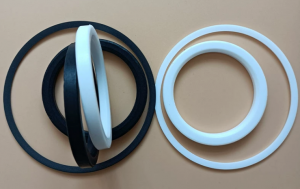

Sealing materials have different requirements and characteristics in various applications and environments. Here are some distinctions among common sealing materials:

- Rubber Sealing Materials: Rubber sealing materials typically exhibit good elasticity and sealing performance, suitable for applications under regular temperature and pressure conditions. Common rubber sealing materials include Nitrile Butadiene Rubber (NBR), Fluoroelastomer (FKM), Ethylene Propylene Diene Monomer (EPDM), among others.

- Polytetrafluoroethylene (PTFE) Sealing Materials: PTFE is a low-friction, corrosion-resistant, and high-temperature resistant material. It offers excellent non-adhesive properties and chemical stability, making it suitable for sealing requirements in high-temperature and highly corrosive media. PTFE is commonly used for valve seat sealing or packing sealing in ball valves.

- Metal Sealing Materials: Metal sealing materials are typically made of metals or metal alloys and possess excellent high-temperature, high-pressure, and corrosion-resistant properties. Common metal sealing materials include stainless steel, copper alloys, titanium alloys, among others. Metal sealing materials are frequently employed in applications involving high-temperature, high-pressure, and severe conditions.

- Plastic Sealing Materials: Plastic sealing materials generally exhibit good chemical stability and corrosion resistance, suitable for applications under regular temperature and pressure conditions. Common plastic sealing materials include Polypropylene (PP), Polyethylene (PE), Polyurethane (PU), among others.

It’s essential to select appropriate sealing materials based on specific application requirements and working environments. When choosing and using sealing materials, factors such as the nature of the medium, temperature, pressure, fluid type, and operating conditions should be taken into consideration. Manufacturers typically provide guidelines and recommendations for selecting suitable sealing materials to assist users in their decision-making process.

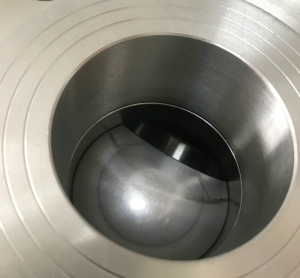

Hard-sealed ball valves are a type of ball valve where the sealing performance is achieved through the contact and sealing of hard materials. Compared to traditional soft-sealed ball valves, hard-sealed ball valves offer better wear resistance, corrosion resistance, and high-temperature performance.

Here are some characteristics and applications of hard-sealed ball valves:

- Sealing Materials: Hard-sealed ball valves typically use hard alloys (such as tungsten titanium alloy), ceramics (such as aluminum oxide), or special coating materials (such as titanium alloy coating) for sealing. These materials exhibit excellent wear resistance, corrosion resistance, and high-temperature performance.

- Wear Resistance: The sealing materials of hard-sealed ball valves have outstanding wear resistance, making them suitable for handling media with solid particles or abrasive properties. They can withstand the scouring and abrasion of high-velocity fluids, thereby extending the service life of the ball valve.

- Corrosion Resistance: The sealing materials of hard-sealed ball valves can resist the erosion of corrosive media, including acids, alkalis, salts, and other corrosive substances. This makes hard-sealed ball valves suitable for applications in corrosive conditions.

- High-Temperature Performance: The sealing materials of hard-sealed ball valves exhibit excellent high-temperature tolerance, enabling them to operate in high-temperature environments and resist the corrosion of high-temperature media. They are commonly used in high-temperature industries such as petroleum, petrochemical, metallurgy, and power generation.

- Application Range: Hard-sealed ball valves are widely used in industries such as oil and gas, chemical, metallurgy, power generation, and water treatment. They are suitable for fluid control and shut-off in high-pressure, high-temperature, corrosive media, and fluids containing abrasive solid particles.

It’s important to select the appropriate hard-sealed ball valve based on specific application requirements and working environments. When choosing and using ball valves, refer to the manufacturer’s product specifications and technical data to ensure that the valve’s materials and design meet the actual needs.

Reviews

There are no reviews yet.