Description

Data Sheet

– Reduced port T port /L port / X port, 1/2~6° (DN15~DN150)

– W.P.:CLASS 150/300 PN16/40 10K

– W.T.:-20°C~180°C

– Investent casting

– Blow-out proof stem

– Live-loading design

– Ant-static device (option)

– 360° Rotary handle

– Locking device handle

– ISO 5211 Direct mounting pad

– Automation accessories (option)

ANSI CLASS 150

– Design: ASME B16.34APlG08. API6D

– Flange dimension: ASME B16.5

– Inspection & testing: AP1 598

DIN PN16

– Design: EN1983, EN12516-1

– Flange dimension: EN1092-1 PN16/40

– inspection & testing: EN12266-1

JIS 10K

– Design: JIs B2071

– Fange diension: JIs B2220

– Inspection & testing: Js B2003

A flanged three-way valve is a type of valve with flange connections and three ports. It enables fluid diversion, convergence, or flow direction control between different directions.

- Flange connections: Flanged three-way valves typically utilize flange connections, which involve fastening and connecting through flange discs and bolts. Flange connections provide robust connections and reliable sealing performance, making them suitable for larger diameter piping systems.

- Three-way design: Flanged three-way valves have three ports, usually labeled as A, B, and C. Depending on the valve’s operation, it can achieve fluid diversion or convergence between ports A and B, or direct fluid from port A or B to port C.

- Flow direction control: By rotating the valve body, the flanged three-way valve can control the flow direction of the fluid. Operators can adjust the valve body’s position using a handle, gear, or electric device to achieve the desired flow distribution.

- Pressure resistance: Flanged three-way valves typically have high pressure resistance, enabling them to withstand higher pressures and flow rates.

- Application range: Flanged three-way valves find wide application in chemical, petroleum, natural gas, water treatment, and other industries. They are commonly used in process control applications involving fluid diversion, convergence, flow rate regulation, and flow direction switching.

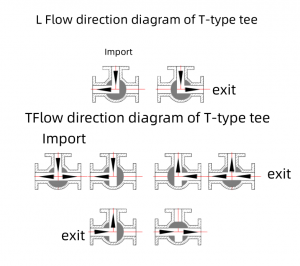

L-type ball valves and T-type ball valves are two common structures of ball valves, and they have some differences in terms of internal channel arrangement and application scenarios.

-

L-type ball valve: The internal channel arrangement of an L-type ball valve forms a right-angle shape. When the ball is in the closed position, the medium can enter from one inlet and flow out through a side outlet. It has the following characteristics:

- Flow direction change: L-type ball valves are suitable for applications that require a change in the flow direction of the medium. They can redirect the fluid from one direction to another, commonly used for diversion or convergence operations in pipeline systems.

- 90-degree rotation: L-type ball valves change the flow direction by rotating the ball, allowing the fluid to change direction within a 90-degree angle.

- Two ports: L-type ball valves typically have two connection ports of different sizes, one for the inlet and the other for the outlet or side outlet.

-

T-type ball valve: The internal channel arrangement of a T-type ball valve forms a “T” shape. When the ball is in the closed position, the medium can enter from one inlet and flow out through one of the two outlets or side outlets. It has the following characteristics:

- Flow diversion: T-type ball valves are suitable for applications that require fluid diversion to two different directions. They can split the fluid from one inlet to two outlets or one of the side outlets.

- 180-degree rotation: T-type ball valves change the flow direction by rotating the ball, allowing the fluid to change direction within a 180-degree angle.

- Three ports: T-type ball valves typically have three connection ports of different sizes, one for the inlet and two for the outlets or side outlets.

Reviews

There are no reviews yet.