Описание

Data Sheet

– Full port, 1/2’~6″ (DN15~DN150)

– W.P.: PN16/40

– W.T.:-20°C~180℃

– Investment casting

– Blow-out proof stem

– Anti-static device (option)

– Design: GB /T 12237

– Flange dimension: HG /T 20592

– Face to face: GB / T 12221

– Inspection & testing: GB / T 13927, JB / T 9092

RF face refers to the Raised Face (RF) surface in flange connections. Raised Face is a common form of flange face used to provide sealing between pipes and valves.

Here are the characteristics of the RF face:

- Raised Surface: The RF face has a raised shape on the flange connection surface, creating a flat sealing area.

- Flange Sealing: The RF face mates with the corresponding flange sealing surface (usually a flat face or RF face) during flange connection, forming a sealing area.

- Flange Standard: The RF face is standardized according to ANSI B16.5 (American National Standard) or other relevant standards, ensuring interchangeability and standardization of flange connections.

The advantages of the RF face include:

- Easy Installation: RF face flange connections have standardized designs and dimensions, making the installation process simple and efficient.

- Good Sealing Performance: The RF face provides a larger contact area and excellent sealing performance, effectively preventing media leakage.

The RF face is widely used in various industries for its reliable sealing properties and ease of installation. It ensures proper sealing between flanges, promoting efficient and secure fluid transportation.

The characteristics of the RJ face are as follows:

- Grooves and Protrusions: The RJ face has a unique structure with grooves and protrusions designed to match the shape of a ring gasket.

- Metal Sealing: The RJ face provides a high level of sealing performance and pressure resistance through the metal-to-metal contact with the ring gasket.

- High Pressure and High-Temperature Applications: The RJ face is typically used in high-pressure and high-temperature applications, such as the oil, chemical, and natural gas industries.

The ring gasket is a type of metal gasket made of hard metal, such as stainless steel. It can withstand the sealing requirements under high pressure and high-temperature conditions. The ring gasket tightly fits with the RJ face and fills the gaps between flanges under pressure, thereby forming a reliable seal.

ZG thread connection refers to a type of thread connection standard in China’s national standard (GB/T). ZG thread connection is commonly used for connecting pipes, valves, and other equipment to achieve sealing and fastening.

Here are some characteristics of ZG thread connection:

- Thread Types: ZG thread connection utilizes a pairing of internal and external threads. The internal threads include straight threads (ZG), taper pipe threads (ZGPT), cylindrical pipe threads (ZGPG), etc. The external threads include straight threads (ZG), taper pipe threads (ZGPT), cylindrical pipe threads (ZGPG), etc.

- Size Standard: The size standard of ZG thread connection follows the national standard (GB/T), ensuring a unified specification and dimension to ensure interchangeability and standardization.

ZG thread connection provides a reliable and standardized method for connecting pipes and equipment in various industries. It ensures a secure and sealed connection in line with the specified dimensions and standards.

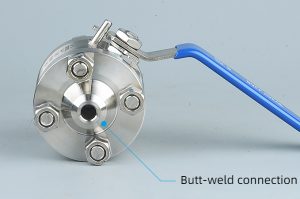

Butt-weld connection is a common method of joining pipes, or connecting pipes to valves and fittings. It involves melting the metal to create a strong and reliable connection, and it has the following characteristics:

- Strength and Reliability: Butt-weld connections tightly join pipes or fittings together through the fusion of metals, creating a continuous and robust connection. It provides high connection strength and reliability.

- Leak-Free: Butt-weld connections achieve a tight seal through the formation of the weld, reducing the risk of leakage. When executed correctly, butt-weld connections can provide reliable sealing performance.

- Integration Advantage: Butt-weld connections integrate pipes or fittings with valves and other components, forming a unified structure. This reduces the number of connection points and joints, improving overall compactness and strength.

- Good Fluid Performance: Butt-weld connections have no protrusions or cavities, minimizing flow resistance and providing excellent fluid performance. They are suitable for applications with high flow velocity and pressure.

Butt-weld connections are widely used in various industries, including oil and gas, chemical, and process piping systems. They offer a secure, leak-free, and efficient method of connecting pipes and ensuring smooth fluid flow.

Отзывы

Отзывов пока нет.