The check valve, also known as a one-way valve or non-return valve, opens and closes based on the flow pressure of the medium within the pipeline. Its main function is to prevent the backflow of the medium while also preventing the reversal of pumps and motors, and eliminating water hammer phenomena.

There are various types of check valves, including swing check valves, lift check valves, butterfly slow-closing check valves, ball check valves, axial flow check valves, dual-plate check valves, and diaphragm check valves. Other types include rubber flap check valves, oxygen check valves, and extraction steam check valves for steam turbines.

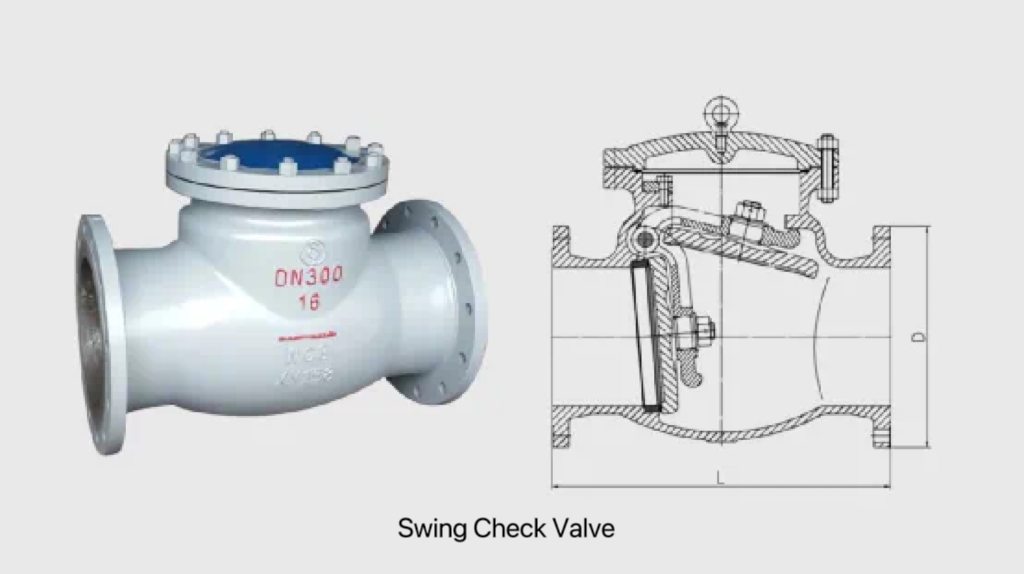

The standard for swing check valves includes GB/T12232-2016 for cast iron swing check valves and GB/T12236-2008 for steel swing check valves used in the petroleum, chemical, and related industries.

A swing check valve is mainly composed of components such as the valve body, valve cover, valve seat, valve disc, rocker arm, pivot pin, and bracket.

The valve disc rotates around the pin outside the valve seat. The back of the valve disc is fixed to one end of the rocker arm through a connecting screw and nut, while the other end of the rocker arm is hinged and installed on the bracket inside the valve body. The medium pressure at the inlet end drives the valve disc to rotate and open, while the pressure at the outlet end and the self-weight of the valve disc cause it to close.

Since the internal flow channel of the valve is essentially a straight line, the flow resistance is smaller than that of lift check valves, making it suitable for large-diameter applications. However, it is not suitable for pulsating flow, and its sealing performance is not as good as that of lift check valves. According to the structure of the valve disc, there are single-disc swing check valves, double-disc swing check valves, and multi-disc swing check valves.

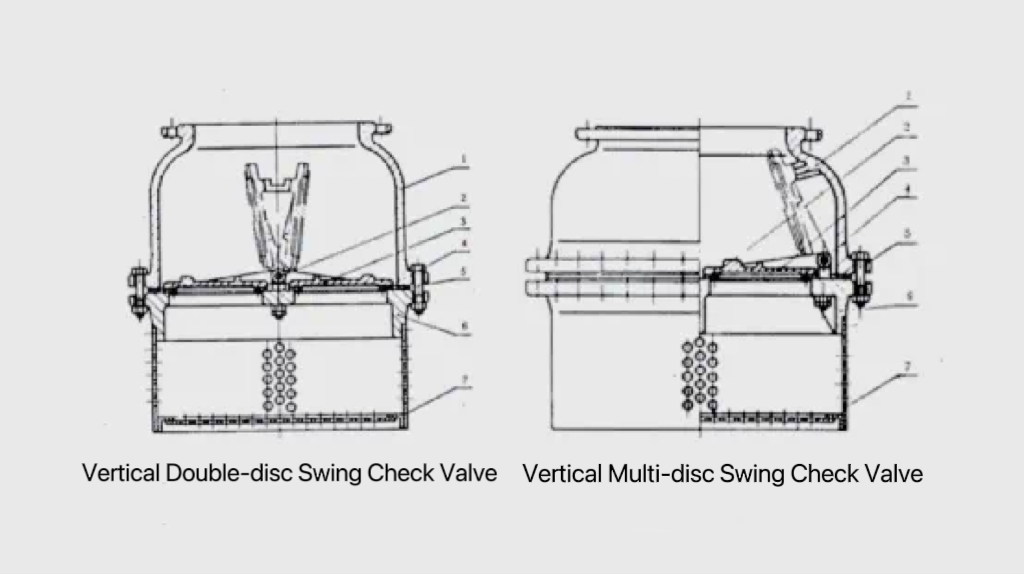

Single-disc swing check valves are suitable for large and medium diameters, with large-diameter single-disc swing check valves often adopting a slow-closing structure to reduce water hammer phenomena (DN50-DN600). Double-disc swing check valves are suitable for large and medium diameters. The dual-plate design, especially in wafer type, has a short structure length and light weight. It can also use a slow-closing structure (DN50-DN1200). Multi-disc swing check valves are suitable for low pressure and extremely large diameter pipelines (DN800-DN1800).

Swing check valves are mainly used in horizontal pipelines but can also be used in vertical pipelines. When used in vertical pipelines, the medium must flow from bottom to top.

Vertical swing check valves are suitable for the suction pipe end of pumps and are only applicable to vertical pipelines.

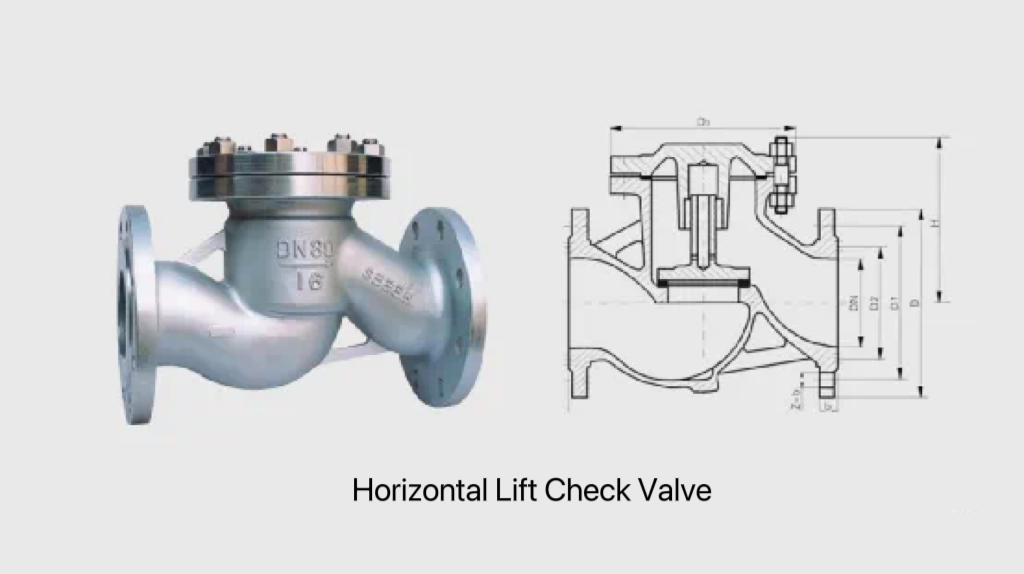

Lift check valve standards: GB/T12233-2008 General Valves – Iron Globe Valves and Lift Check Valves. GB/T12235-2007 Steel Globe Valves and Lift Check Valves for Petroleum, Chemical, and Related Industries.

The lift check valve is composed of components such as the valve body, valve cover, valve seat, and valve disc.

The valve disc moves along the cavity of the valve body. The valve disc opens under the fluid pressure at the inlet end, allowing the medium to flow from the inlet to the outlet. When the pump stops, if the inlet pressure is lower than the outlet pressure, the valve disc, influenced by factors such as the pressure difference in the medium and its own weight, automatically closes to prevent backflow of the medium. This type of valve is suitable for medium and small-diameter pipelines.

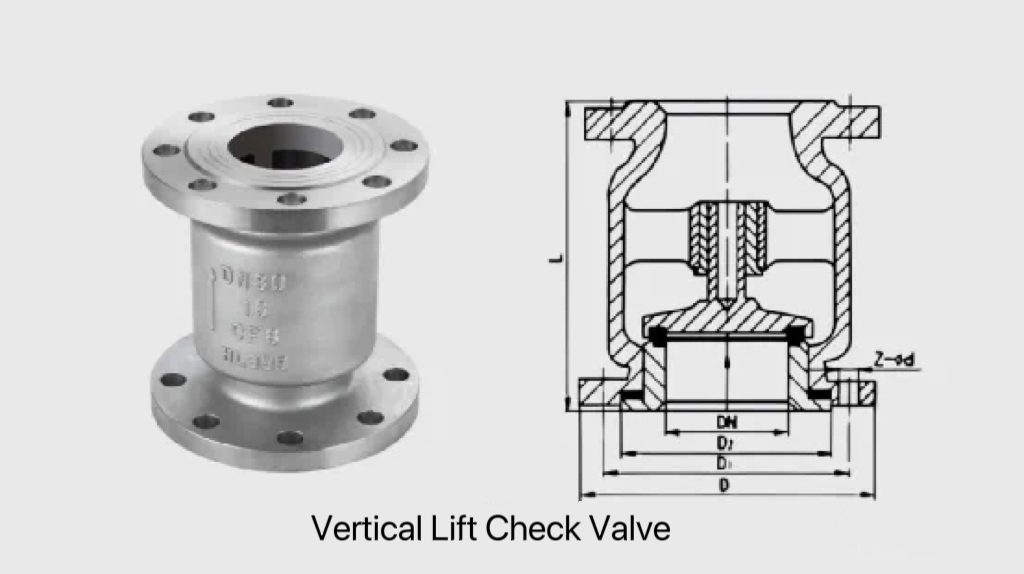

Lift check valves are mainly classified into horizontal and vertical types based on the installation method.

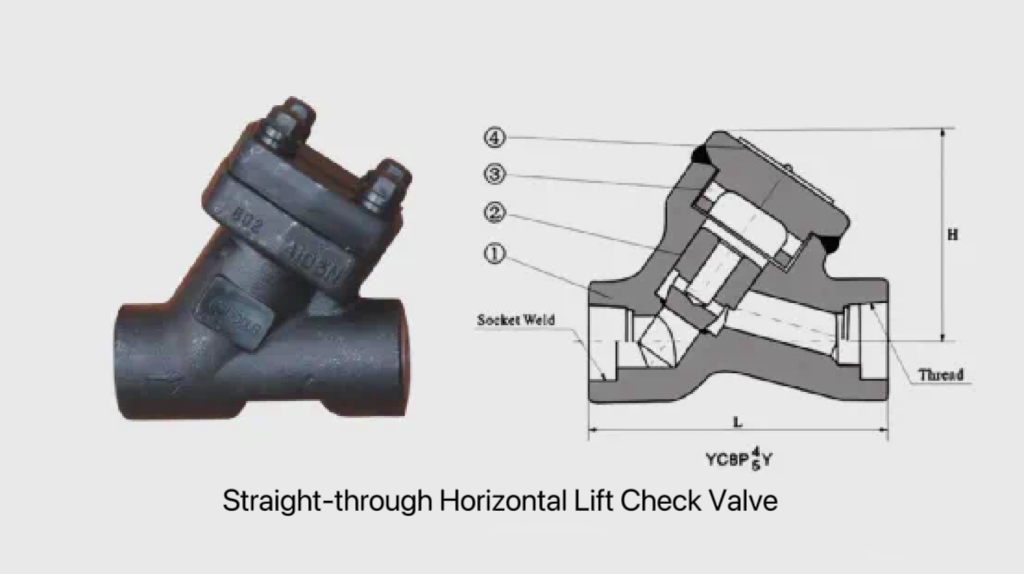

In the case of straight-through horizontal lift check valves, the direction of the inlet and outlet flow channels is perpendicular to the direction of the valve seat channel. They are suitable for DN15-DN300. Generally, they can only be installed in horizontal pipelines. There are also inclined straight-through horizontal lift check valves, where the flow channel direction is inclined at a certain angle to the valve seat channel, reducing flow resistance compared to straight-through lift check valves.

Vertical lift check valves have the same direction for the inlet and outlet flow channels as the valve seat channel. They have slightly lower flow resistance compared to straight-through types. They are available in sizes ranging from DN15 to DN300 and are typically installed in vertical pipelines where the medium flows from bottom to top.

For bidirectional silencing check valves, dual-purpose check valves for vertical and horizontal installation, and axial flow check valves, they can be installed both in vertical and horizontal pipelines. These valves offer flexibility and versatility, making them suitable for various pipeline configurations and flow directions.

The differences between swing check valves and lift check valves are as follows:

Valve Structure:

Swing Check Valve: The structure is an internally mounted rocker arm swing type. All the opening and closing components are inside the valve body, not penetrating through the body. The connection between the arm and the valve disc uses a ball-and-socket structure, providing the valve disc with a certain degree of freedom within a 360° range, allowing for slight positional compensation.

Lift Check Valve: The valve body is similar to a globe valve structure, with grooves on the valve cover for the upward and downward movement of the valve disc. The valve disc can move freely in an upward and downward direction and may have a spherical or plug-shaped design. Springs can be added to reduce the opening impact force and assist in the rapid closing of the valve, though it increases the opening flow resistance.

Suitable Installation for Pipelines:

Swing Check Valve: Can be installed on both horizontal and vertical pipelines. When installed vertically, the medium must flow from bottom to top.

Lift Check Valve: Straight-through horizontal lift check valves can only be installed in horizontal pipelines. Vertical lift check valves are suitable for vertical pipelines, where the medium flows from bottom to top.

Differences in Medium Flow Resistance:

Swing Check Valve: When the diameter is above DN50, using a swing check valve is more energy-efficient with lower pressure drop.

Lift Check Valve: The flow channel in straight-through horizontal lift check valves has an S-shaped bend, whereas the flow channel in swing check valves is closer to a straight line. Therefore, the flow resistance of straight-through horizontal lift check valves is higher than that of swing check valves. Direct-flow lift check valves have a mostly straight flow channel, effectively reducing flow resistance.

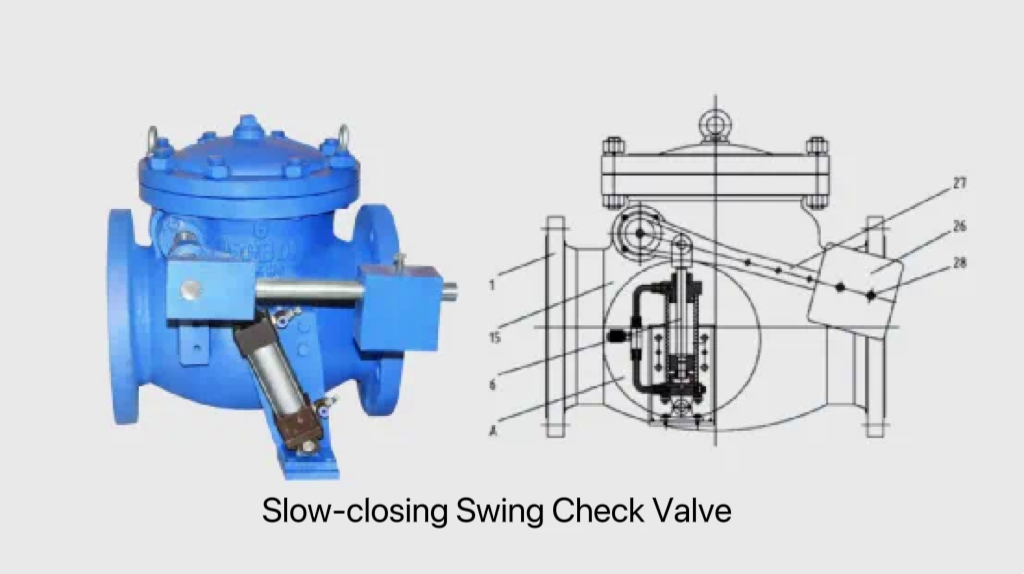

Application in Slow-Closing Check Valves:

Swing Check Valve: Can be easily modified by adding accessories outside the valve body to become a slow-closing check valve, making it widely applicable.

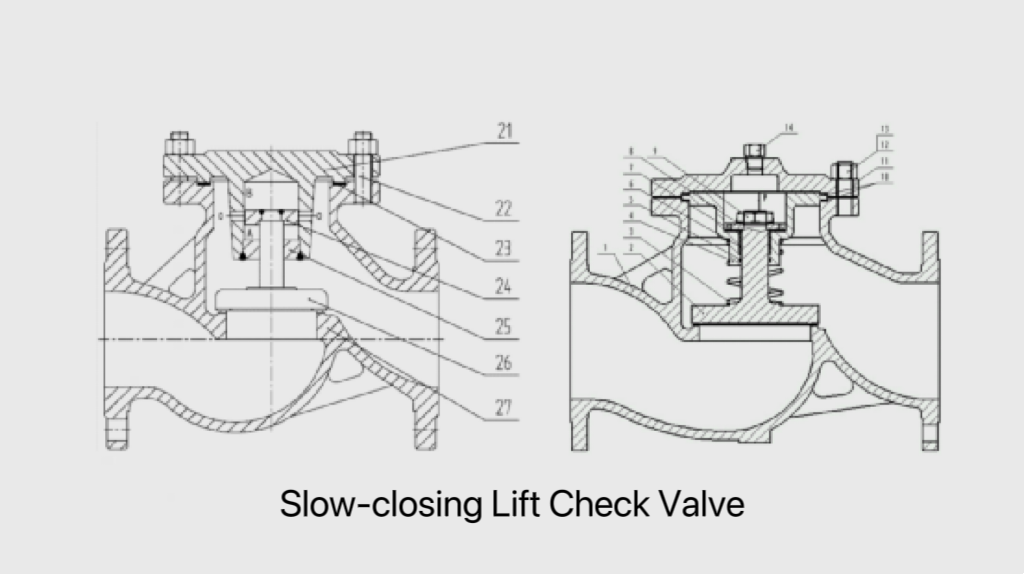

Lift Check Valve: Typically requires internal structural changes for application in slow-closing check valves and is less commonly used in this context. The swing check valve’s disc needs to rotate a certain angle, close to 90 degrees. Adding a slow-closing mechanism, heavy hammer, or slow-closing cylinder on the pivot shaft can transform it into a slow-closing swing check valve. In contrast, a slow-closing butterfly dual-disc check valve involves adding a slow-closing cylinder on the valve body.

Lift check valves are usually modified internally to alter the lifting speed of the valve disc, transforming them into slow-closing check valves.

Wider Application of Swing Check Valves:

Swing check valves are applicable across a wide pressure range, from low to high pressure. Specific application requirements are outlined in standards such as GB/T12236 (Chinese standard), API6D (American standard), and BS1868 (British standard). This broad spectrum of standards indicates the extensive applicability of swing check valves.

The urban construction industry standard CJ/154-2001 outlines general technical requirements for slow-closing check valves used in drainage systems. This includes swing-type slow-closing check valves, both single-disc (single-disc swing slow-closing check valves) and double-disc (butterfly dual-disc swing slow-closing check valves). Both of these fall under the category of swing check valves, differing only in the presence of a single or double disc.