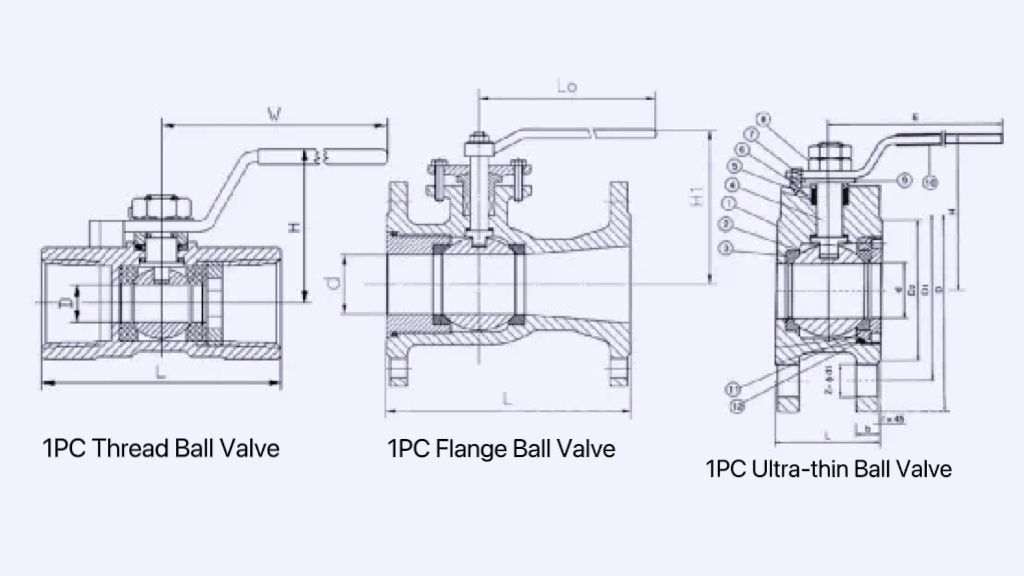

The structure and characteristics of a one-piece ball valve

The one-piece ball valve, named for its integral structure, features a compact and lightweight design. The ball core, valve seat, and valve stem are inserted into the flow passage from one side of the valve body. Due to size limitations in the valve body passage, the full-diameter ball core cannot be accommodated inside the valve body. Therefore, the flow passage of the one-piece ball valve is reduced in diameter. Its flow capacity is subject to certain limitations. It holds a cost advantage and is primarily used in low-pressure pipelines.

The one-piece ball valve is available in threaded, flanged, and clamp connections. Threaded connections typically use a 55° taper pipe thread to achieve better sealing performance. Flanged connections offer convenient installation. Clamp connections have a shorter structural length and can be installed in compact space pipelines. The valve is constructed using materials such as WCB cast steel, stainless steel CF8, CF8M, and others.

One-piece threaded ball valves, due to their shallow stem packing chamber and minimal sealing filler, are often used in low-pressure pipelines.

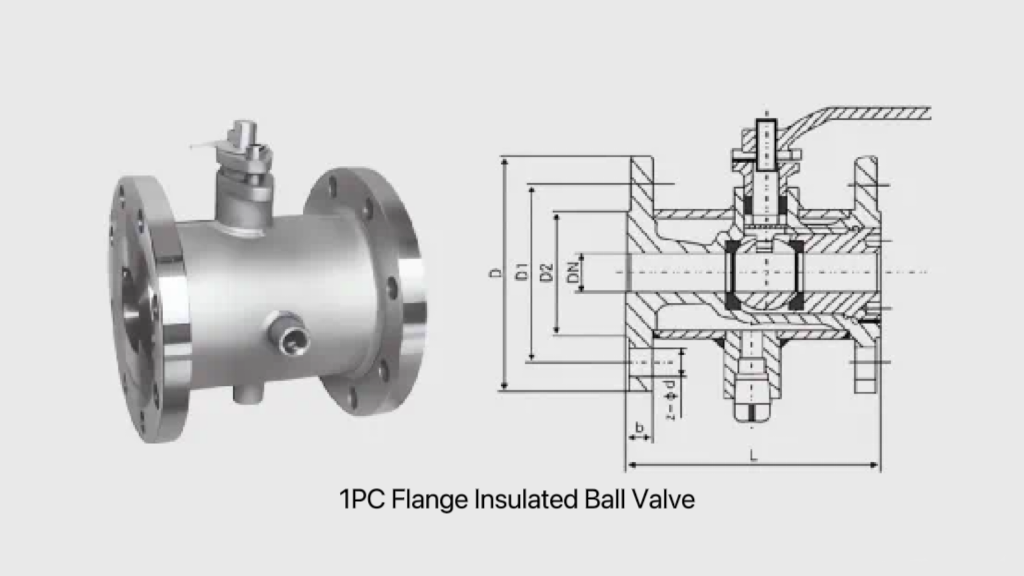

One-piece flanged ball valves can be designed as high-temperature drain valves, effectively preventing the medium from leaking externally from the valve body. This design avoids the risk of medium leakage between the body of two-piece and three-piece ball valves. They can be used for steam and heat-conducting oil media. They can also be insulated ball valves, suitable for transporting easily crystallizing or solidifying media. Hot water or steam can be introduced into the insulation shell to provide insulation for the ball valve.

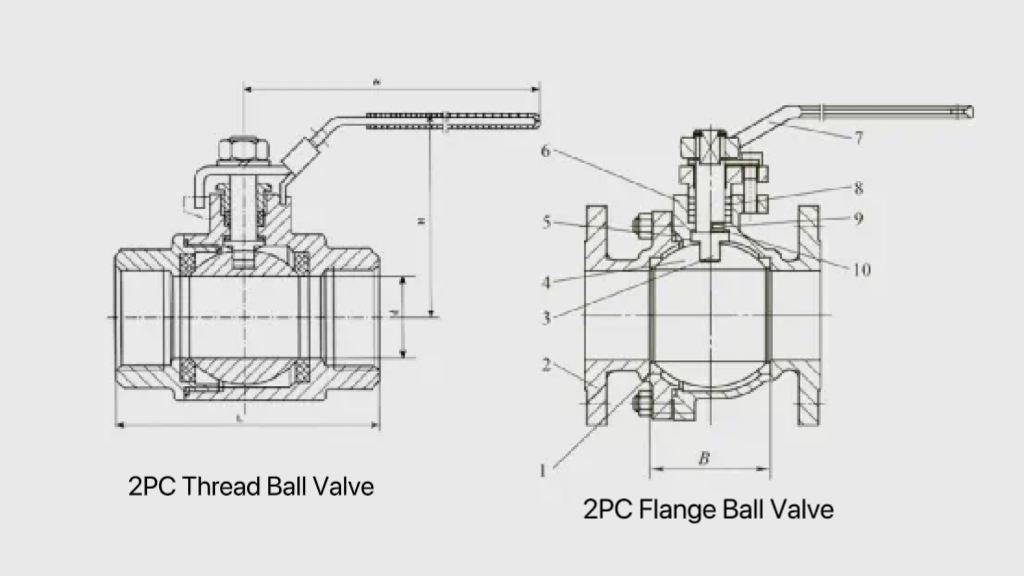

The structure and characteristics of a two-piece ball valve

The two-piece ball valve consists of a main valve body and a secondary valve body, hence the name “two-piece ball valve.” It is a commonly used type of ball valve. After the ball core, valve seat, and valve stem are assembled into the main valve body, the secondary valve body is connected to the main valve body through threads or bolts. Its ball core passage is of full-diameter size, resulting in low flow resistance and high flow capacity.

Two-piece ball valves have internal thread connections, external thread connections, and internal-external thread connections. Threads typically use a 55° taper pipe thread for good sealing performance. Two-piece flanged ball valves are widely used.

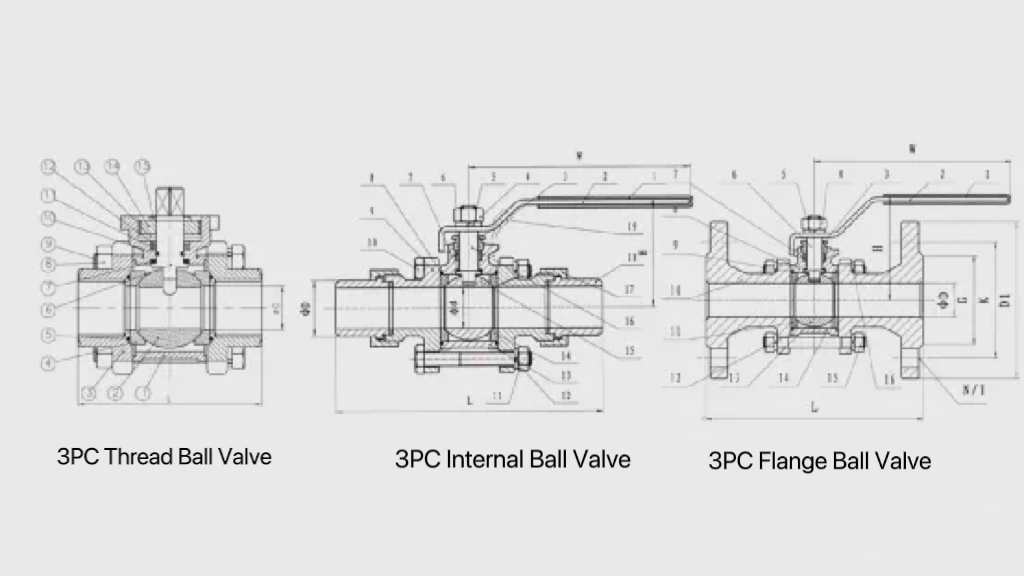

The structure and characteristics of a three-piece ball valve

The three-piece ball valve consists of a main valve body and two secondary valve bodies, hence the name “three-piece ball valve.” After the ball core and valve stem are assembled into the main valve body, the secondary valve bodies are inserted into the valve seats, and the main and secondary valve bodies are connected together by bolts to form a complete unit. Its ball core passage is also of full-diameter size.

Three-piece ball valves also come with internal thread connections and external thread connections. Internal threads typically use a 55° taper pipe thread for good sealing performance. External threads come with welding joints, allowing them to be welded to pipelines. The disassembly and assembly are more convenient during maintenance, avoiding the need for a separate union for internal thread connections.

Butt welding and socket welding connections can be used, and extended pipe connections can also be adopted during welding. This helps avoid high-temperature damage to the valve seat seals and stem packing during welding, reducing the installation difficulty.

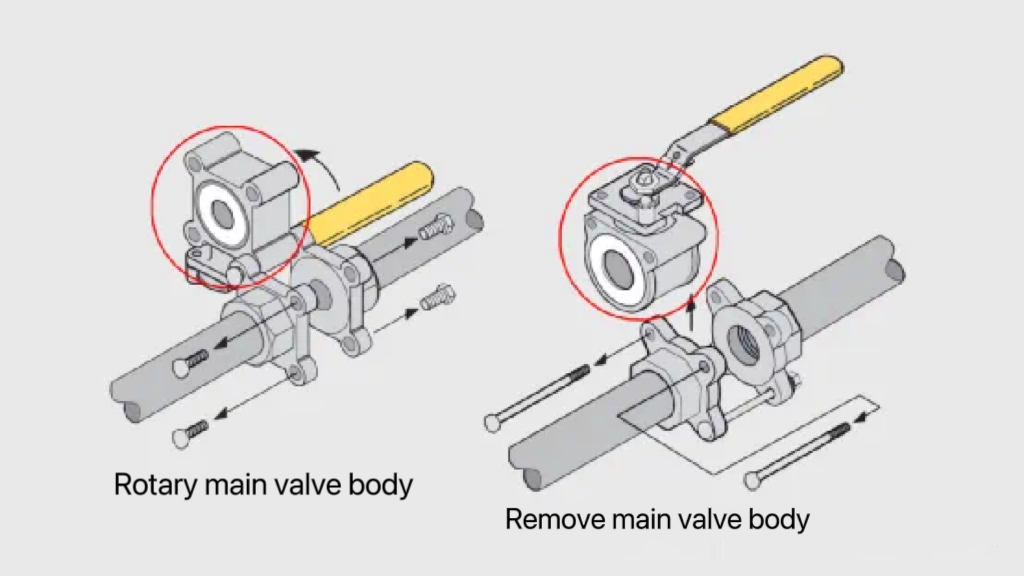

The main feature of the three-piece ball valve is its ability to be maintained online, making it extremely convenient. By loosening the screws on the valve body, a bolt passing through the main valve body can be removed. Rotating the main valve body allows for the replacement of the valve seat seals. The entire main valve body can be removed for maintenance by completely removing the bolts, while the secondary valve bodies remain in the pipeline. This avoids the need to dismantle the entire ball valve, significantly reducing the workload for maintenance.

The difference between 1PC ball valve, 2PC ball valve and 3PC ball valve

1. Different valve body structures

The one-piece ball valve has an integral valve body, the two-piece ball valve has a main and secondary valve body, and the three-piece ball valve has one main valve body and two secondary valve bodies, making a total of three parts.

2. Different ball core passage sizes

The one-piece ball valve uses a reduced-diameter passage, which affects flow capacity. The two-piece and three-piece ball valves use full-diameter passage sizes, resulting in lower flow resistance and greater flow capacity. For applications with flow requirements, the two-piece and three-piece ball valves can be chosen.

3. Different installation and maintenance workloads

The three-piece ball valve is more convenient for installation and maintenance compared to the one-piece and two-piece ball valves, with a smaller workload. It facilitates the replacement of valve seat seals, ball cores, packing, and other components.

4. Different procurement costs

For the same specifications, the three-piece ball valve has the highest cost, followed by the two-piece ball valve, and the one-piece ball valve has the lowest cost.