The design standards for butterfly-type slow-closing check valves are: CJ/T282-2008, JB/T 5299-1998, CJ/T154-2001, and JB… Butterfly water pump control valve.

The butterfly check valve has a rotating butterfly plate around the internal hinge shaft within the valve seat. Similar to a butterfly valve, the rotating hinge shaft passes through the valve passage, and the butterfly plate is oriented vertically or inclined to the flow channel.

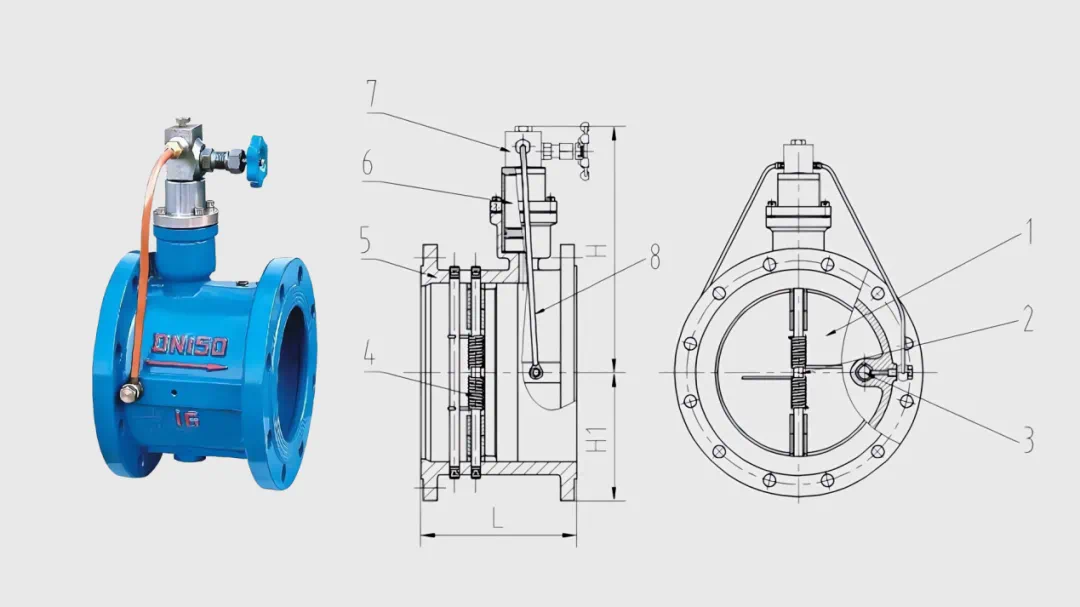

1. HH47X, HH47H Butterfly Slow-Closing Check Valve

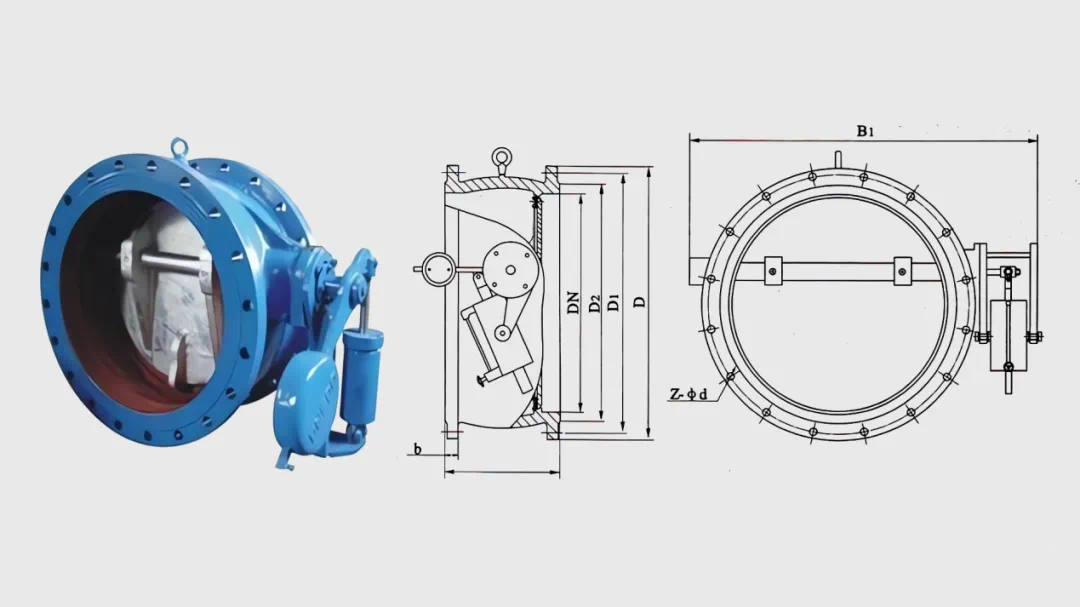

Butterfly slow-closing check valve is installed at the pump outlet. The butterfly plate is driven to open by the medium pressure. When the pump stops abnormally, the butterfly plate, under its own gravity and the reverse pressure of the medium, rapidly closes about 80% first. Then, through the damping action of the slow-closing hydraulic cylinder, it slowly closes the remaining 20% to prevent destructive water hammer phenomena during pump shutdown.

The butterfly slow-closing check valve, also known as the butterfly buffering check valve, is mainly composed of major components such as the valve body, butterfly plate, and damping oil cylinder. The valve seat is inclined, and the butterfly plate adopts a double eccentric or triple eccentric design.

In the case of small diameter, it is a single butterfly plate structure. In the case of large diameter, a structure with a large butterfly plate and a small butterfly plate is used. The valve shaft deviates radially from one side of the flow channel, not in the middle of the butterfly plate.

At the same time, the butterfly plate is inclined by about 20°, which shortens the stroke of the valve plate during opening and closing. Therefore, the opening and closing time of the valve plate is relatively short, achieving the purpose of rapid valve opening and closing.

Simultaneously, during the closing and falling process, the valve plate can save power by relying on its own gravity. The advantage of the inclined butterfly plate is also to reduce the friction between the sealing surfaces of the valve seat and the valve plate, extending the service life of the sealing surface. The valve diameter can reach DN2000.

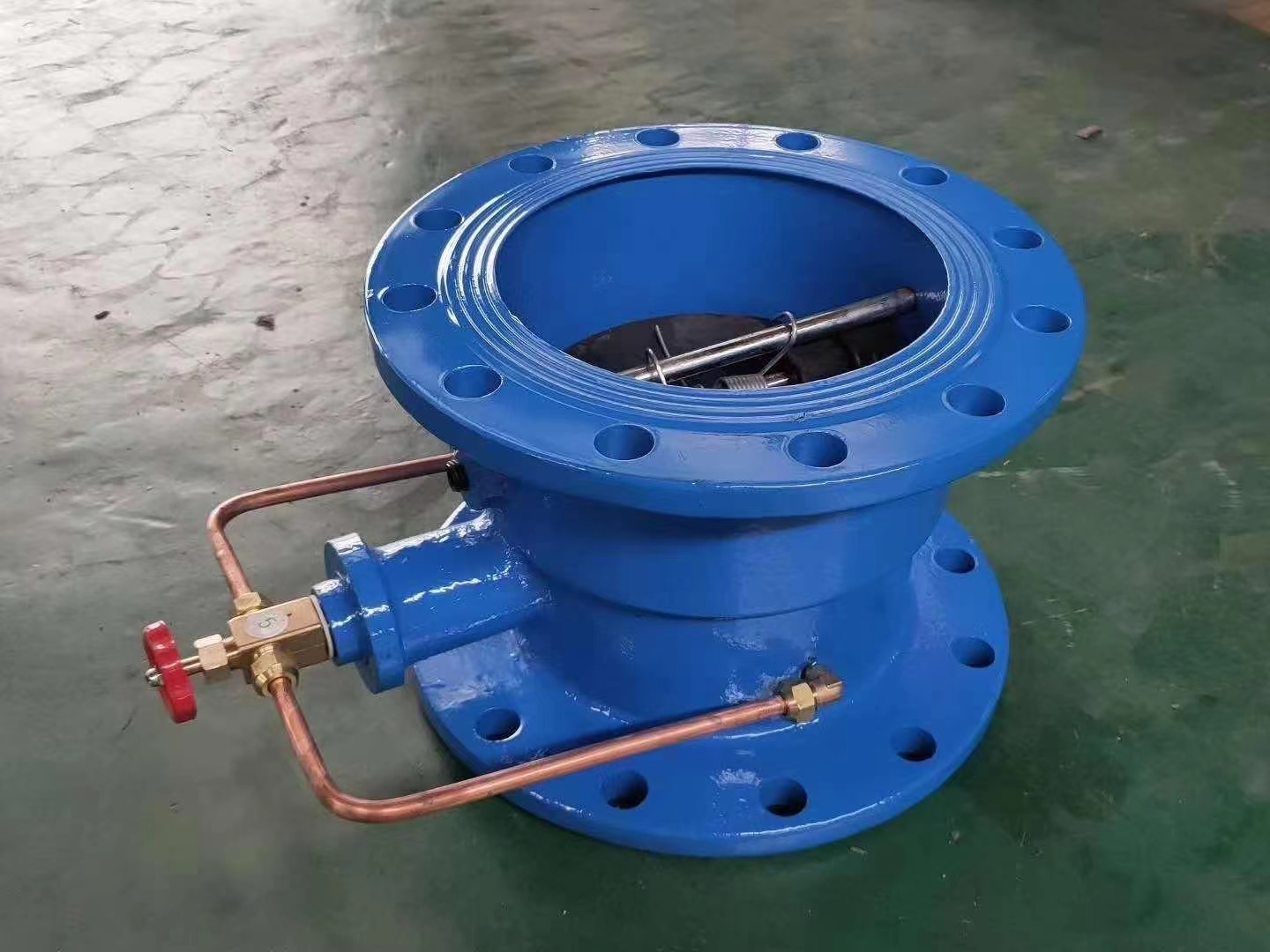

2. Hydraulic Automatic Control Valve

The hydraulic automatic control valve, also known as the hydraulic automatic valve, is an improvement based on the butterfly slow-closing check valve. Hydraulic cylinders for slow closing are connected to both sides of the valve’s inlet and outlet. It relies on the pressure of the medium in the pipeline to drive the hydraulic cylinder for slow closing. This design avoids the failure of slow closing due to hydraulic oil leakage from an external hydraulic cylinder and prevents destructive water hammer phenomena.

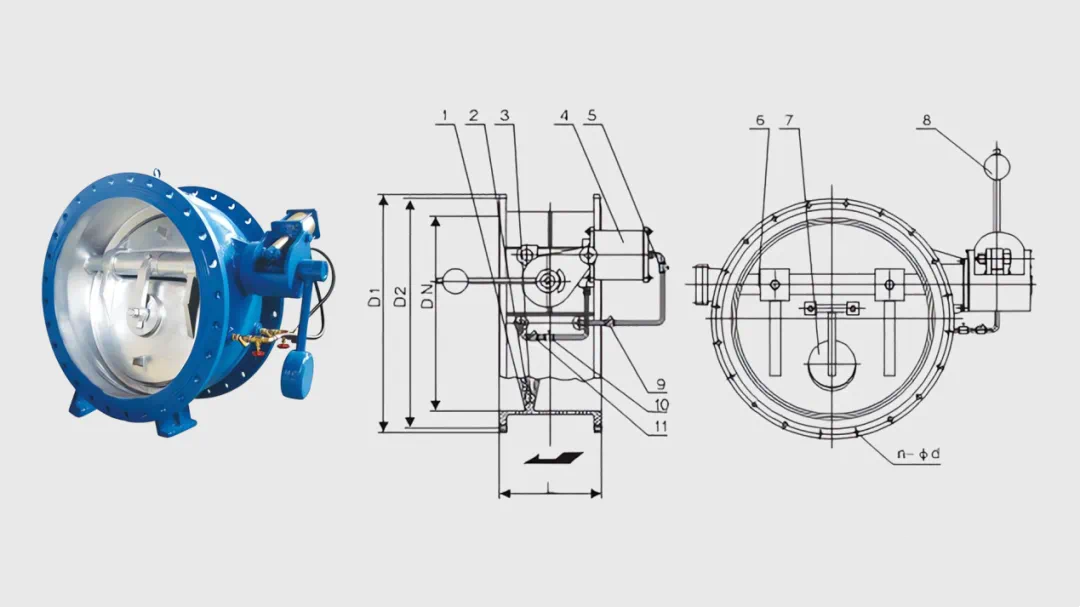

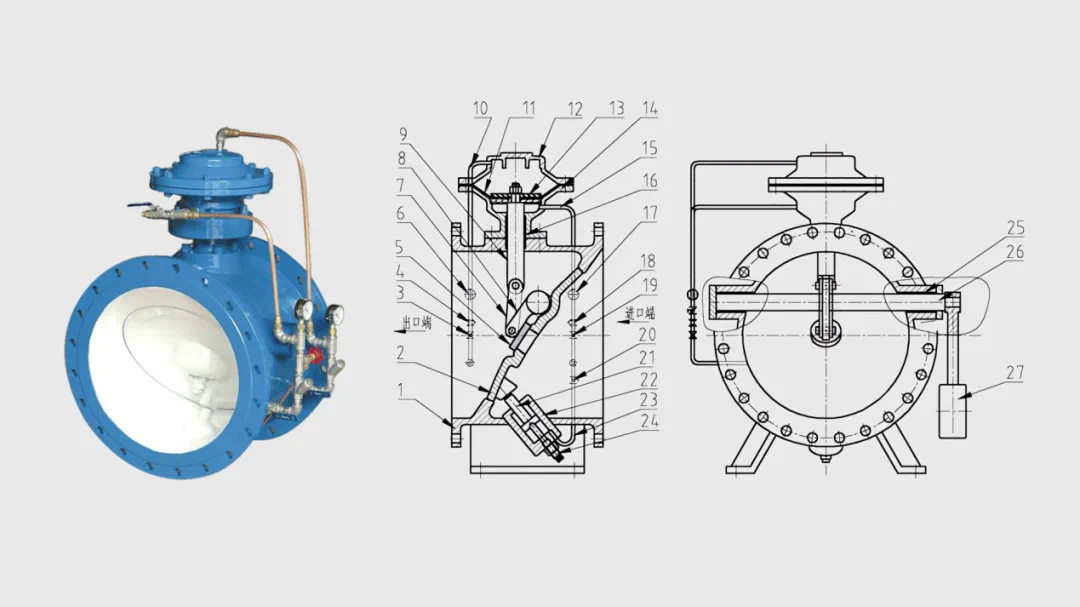

3. HH46X, HH48X, HH49X Micro-Resistance Slow-Closing Butterfly Check Valve

The micro-resistance slow-closing butterfly check valve is mainly composed of the valve body, two semicircular valve discs, return springs, oil storage piston cylinder, damping piston (slow-closing piston cylinder), and needle valve (micro-adjustment valve).

The double-disc structure is essentially a rotary lift check valve. The flow passage is divided into two parts, and each part of the butterfly plate is rotary lift. It is also known in the industry as the micro-resistance slow-closing butterfly-type noise reduction check valve. The valve diameter can reach DN1600.

The hydraulic cylinder for slow closing contains hydraulic oil, and the closing speed is adjusted by the opening degree of the needle valve. There are two slow-closing pistons on the valve body corresponding to two valve plates. After the two valve plates close rapidly, they press against the extended push rod of the slow-closing piston. The piston is then pushed back into the piston, and the valve plate slowly closes with it, eliminating water hammer phenomena.

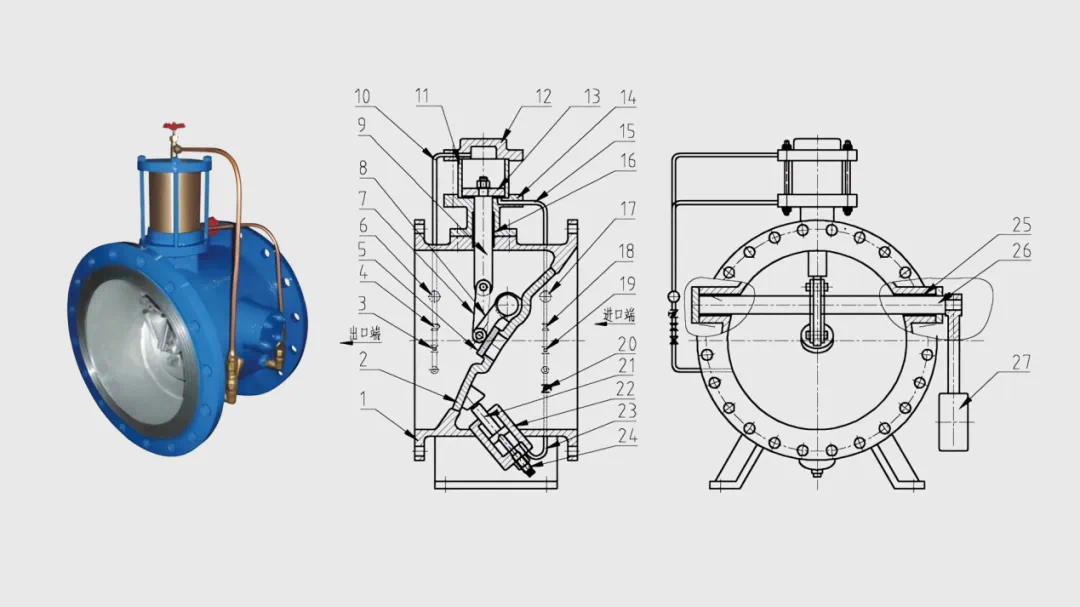

4. BFDG7m41HX Pipe Force Valve, also known as the butterfly water pump control valve.

It consists of the valve body, large valve plate, small valve plate, valve stem, control rod, diaphragm chamber (piston cylinder), diaphragm (piston), and control pipeline, providing functions such as preventing backflow, light load start-up of the pump, and reducing water hammer. The diameter can reach DN3000, PN40. It is the latest improved form of the butterfly slow-closing check valve.

The pipe force valve can achieve two-stage valve closure. The large valve plate closes rapidly, cutting off most of the backflow medium to prevent high-speed reversal of the pump. The small valve plate closes slowly, discharging a small amount of backflow medium, significantly reducing water hammer pressure to prevent overpressure-induced water hammer accidents. The closing time is adjustable. For diameters above DN400, there is a piston-type slow-closing device when the large valve plate closes, preventing impact on the valve body sealing surface.

The control chamber of the pipe force valve has two types: diaphragm-type and piston-type.

The diaphragm-type control chamber is suitable for low-pressure pipelines. It is sensitive in response and, unlike the piston-type, is less likely to experience jamming in the presence of impurities in the medium.

The piston-type control chamber is suitable for high-pressure pipelines, with a long service life and easy maintenance.

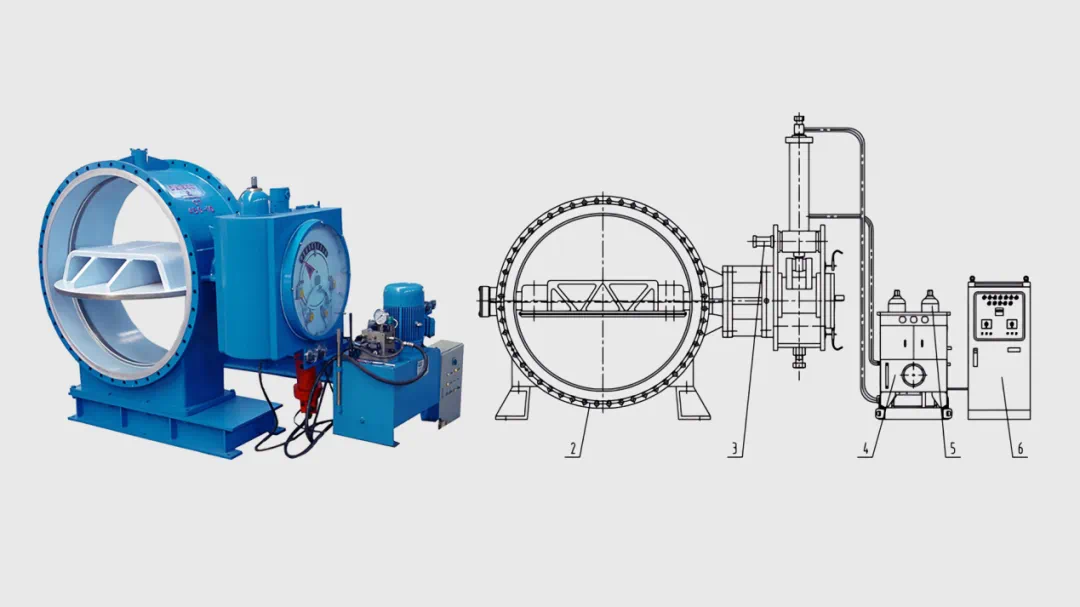

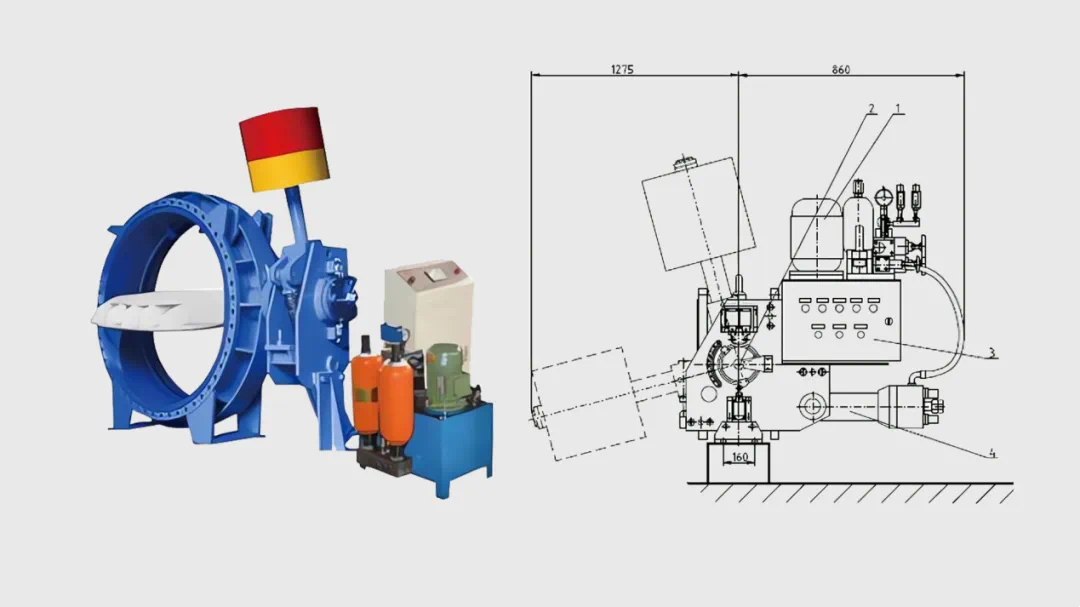

5. HD741X Hydraulic Control Slow-Closing Butterfly Check Valve.

The hydraulic control slow-closing butterfly check valve is primarily installed at the inlet of hydropower station turbines, serving as the inlet valve for turbines, or installed at the pump outlets of various pump stations in water supply, electricity, drainage, and other applications. During operation, it coordinates with the pipeline host to achieve variable-speed check and shut-off functions. When closing, the first 70 degrees close rapidly, followed by a slow closure for the remaining 20 degrees. This effectively eliminates water hammer in the pipeline, ensuring the safety of the pipeline system. Electrical control is achieved through PLC, and the valve diameter can reach DN5000 with a pressure rating of PN40.

It mainly consists of three parts: electrical control device, hydraulic control device, and butterfly valve. There are two types: the hammer-type hydraulic control slow-closing butterfly check valve and the energy storage-type hydraulic control slow-closing butterfly check valve.

In the hammer-type hydraulic control slow-closing butterfly check valve, a heavy hammer is equipped on the valve shaft. Opening the valve is achieved by hydraulic oil pushing the piston cylinder to drive the butterfly valve open, simultaneously lifting the heavy hammer. When closing the valve, the heavy hammer descends, driving the butterfly plate to close.

In the energy storage-type hydraulic control slow-closing butterfly check valve, the opening and closing are achieved by switching the solenoid valve, altering the direction of hydraulic oil entering the hydraulic cylinder to control the valve plate’s switching process. This design replaces the heavy hammer structure with an accumulator, resulting in a smaller size and reduced weight. It gradually replaces the hammer-type structure.